igus polymer compounds in the EN45545 evaluation process

Thorsten Mersch | 24. April 2020

In order for an assembly or component to be allowed for use in a modern rail vehicle in Europe, the components must be tested and evaluated according to EN45545. This is a very time-consuming, bureaucratic process.

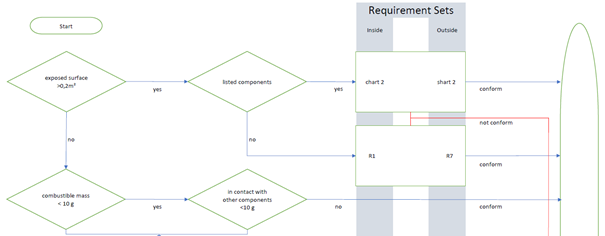

The exposed surface, the weight of the component, and many other points must be considered for selection.

So where can igus products help you develop a compliant design?

First, let us consider various materials. igus has more than 60 materials categorised as iglidur (for bearing technology) and igumid (for energy chains). Each of these materials has its justification. iglidur G is the standard in the area of plain bearings. It is the right solution for most applications. But there are also special materials such as iglidur X for high temperature and chemical resistance. Only two materials fulfil EN45545 (HL3), however. One of them is iglidur RW370 for bearing technology. It can be used for plain bearings, sliding plates, and special parts such as extruded profiles. The second material is igumid GV0 GF. It is used primarily for energy chains.

So does it make sense to manufacture all wear-resistant parts from these materials? The answer is that it does for many, but not for all.

If you consider the first few criteria, you will quickly notice that plain bearings actually don’t need to comply with EN45545.

For one thing, plain bearings are almost always pressed into a metallic support, and a metallic shaft is fed through the bearing. This means that only the bearing’s front surfaces are considered to be exposed. For another thing, most bearing points are so small that the plain bearing’s weight remains under 10 grams. This means that the component is already compliant. So any iglidur material can be used.

But what if the components are larger? Three examples are a guide rail for a sliding door, an energy chain in the space between railway cars and a sliding plate in a bogie.

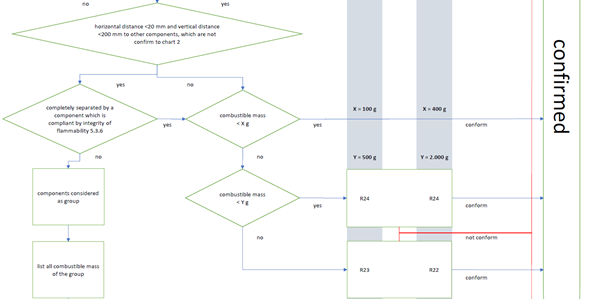

All three examples exceed 10 grams. So the next step is to determine whether the component is near other flammable components. Let us assume that the sliding plate in the bogie has contact only with non-flammable components or is at least 20 or 200mm from them. Since we are outdoors, it is sufficient if the plate weighs less than 400 grams. All iglidur materials would be considered compliant here as well.

But the energy chain can quickly exceed 400 grams. An E4.56 chain weighs more than 3kg/metre. This means that the chain must meet requirement R24 if it weighs less than 2kg and R22/R23 if it weighs more. igumid GV0 GF is the only material that would work for the chain.

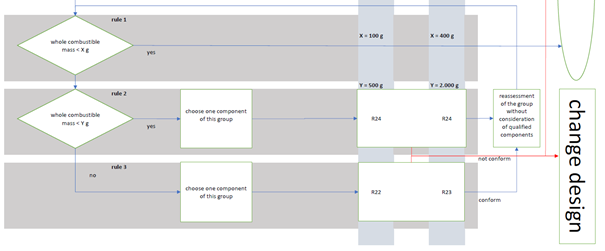

For the guide rail, let us assume that the entire door system (including rubber seals, plastic handles, etc.) has a flammable mass of 1,600 grams. This would normally mean that the system is not compliant.

Now we have to proceed component by component. Let us assume that the guide rail is the largest and heaviest flammable component in the sliding door. The material would then have to fulfil requirement R22 or R23 in order to be removed from the assembly calculation. This restricts us to iglidur RW370 if we are to reduce the overall flammable mass. If we assume that the rail weighs 800 grams, it is still not enough to make the door system compliant. We would have to take another look at the assembly and remove other components, such as seals, from the calculation. We continue this process until a compliant mass is achieved.