iglidur I8-ESD: abrasion-resistant components with ESD specifications

Paul Gomer | 5. May 2020

Every machine contains moving parts that cause friction during operation. In contrast to metal, components made of wear-resistant iglidur polymers do not require additional lubrication (because they contain solid lubricants) – however polymers cannot dissipate the electrostatic discharge caused by friction. In semiconductor and electrical engineering, a static discharge through components can cause permanent damage to the product, even if the discharge is not perceptible to humans. In order to permanently protect these components from irreversible damage, a controlled discharge is necessary, i.e. materials with defined surface resistances must be used which are neither insulating nor conductive, i.e. statically or antistatically conductive.

With iglidur I8-ESD, igus is now launching a laser sintering material on the market, that enables the additive production of prototypes, serial parts and spare parts with ESD specifications. In addition to energy chains, bearings and bar stock with antistatic specifications, customers can now also quickly obtain manufactured, individual ESD polymer components as single pieces or in large volumes.

What distinguishes an ESD material?

The danger of electrical discharge is generally referred to as ESD (electrostatic discharge). The cause of an electrostatic discharge is the friction of two insulating materials against each other. In everyday life we encounter this physical phenomenon e.g. when lightning strikes during a thunderstorm, when we touch door handles or when we walk over carpets with plastic shoes. The surface resistance for the ESD area must therefore be less than 1012 and greater than 106 Ohm, otherwise the material is considered insulating or conductive. In most material data sheets, the electrical specifications are given by the characteristic values spec. volume resistance (Ωxcm) and/or as surface resistance (Ω). [Source: Technical article: ESD – the invisible danger, ELV Journal 04/2010, Matthias Schmidt]

Further information about components made of antistatic polymers can be found in our article about plain bearings for EX and ATEX areas.

The material properties of iglidur I8-ESD

The new laser sintering material iglidur I8-ESD was developed especially for applications in which the dissipative electrical material properties should protect sensitive electronic components.

In addition to the static conductivity, iglidur I8-ESD has a high abrasion resistance compared to a standard PA12 laser sintering material, making it ideal for all applications where electrostatic charges must be avoided. The outstanding specifications at a glance:

- Lubrication-free and maintenance-free

- Abrasion resistance

- Electrostatically dissipative (ESD)

- Colour: black (solid)

- Increased rigidity

- Available as laser sintering powder or 3D printing service in 1-3 days

The material data sheet for iglidur I8-ESD is available for download here.

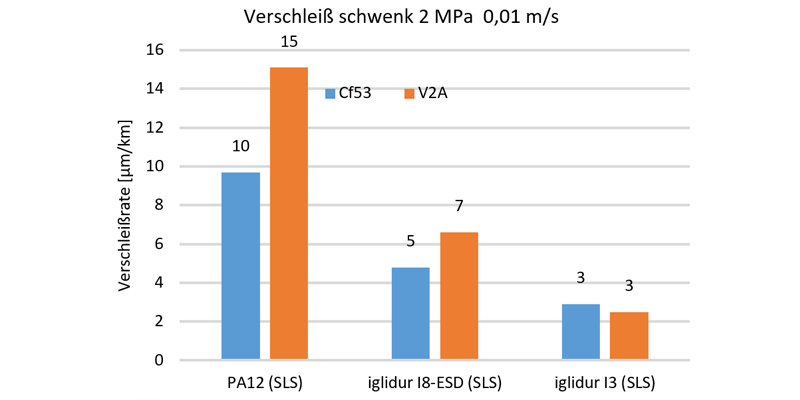

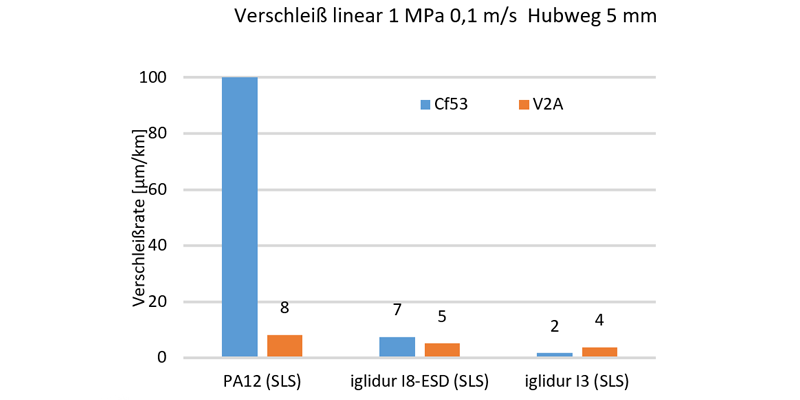

Wear properties in comparison

Like all iglidur materials, iglidur I8-ESD has also been subjected to numerous tests regarding its coefficient of friction. The high abrasion resistance of iglidur I8-ESD was confirmed in practical wear tests. Whether in linear or pivoting application, iglidur I8-ESD shows a wear rate that is two times better than regular laser sintering materials in pivoting.

Why is conductivity slightly dependent on direction?

In most materials for the powder bed based laser sintering process the mechanical properties are dependent on direction (i.e. anisotropic). The tensile strength in the XY plane is often many times better than that in the XZ/YZ plane manufactured in the direction of assembly. In practice, the layer strength in the plane is higher than the strength between the layers.

In addition to the concentration of conductive fillers, the electrical conductivity of polymers depends on the particle distribution in the polymer The process-specific coating application during laser sintering by a doctor blade or a roller, leads to an increased alignment of the fillers and overall to a greater non-homogeneity of the filler distribution. Therefore, the measured electrical conductivity in the assembly direction is lower (higher surface resistance). For iglidur I8-ESD, the direction-dependent difference in the specific contact resistance lies between 3.4*106 Ωxcm and 2.8*107 Ωxcm. (Cf. data sheet). However, the differences are within the range for ESD-compatible materials.

Buy iglidur I8-ESD as material or print components

Since iglidur I8-ESD is suitable for processing by regular laser sintering, it can be purchased as laser sintering powder and processed on your own equipment. Those who do not have their own laser sintering system or only need a few parts from it, can order the components from the igus 3D printing service – delivery takes 1-3 business days.

Do you have questions about iglidur I8-ESD or need support in planning a project with it? We would be happy to advise you personally by telephone or on site.