How to secure bearings properly – Part 3: Anti-rotation features

Lars Butenschön | 27. November 2018

In episode two of this series, I showed you some options of how to secure bearings axially to keep them from moving out of housing holes. In this episode, I want to show you how to make an easy anti-rotation feature and why you would need one in the first place.

Why would you need an anti-rotation feature?

A plain bearing system typically works like that: The press-fit in the housing hole keeps the bearing in place. The bearing supports the moving shaft. The low coefficient of friction on the inner diameter of the plain bearing allows the shaft to rotate easily. Since the plain bearing is usually significantly less expensive than the shaft, it is designed to be a wear part. That means you just need to replace the plain bearing once in a while and not the more expensive shaft.

That is why many metal plain bearings are lined with a thin PTFE layer on the inner diameter. The metal outer layer serves as the backbone of the bearing, while the PTFE layer keeps the shaft running smoothly. Plastic bearings are more flexible. They offer sliding capabilities on both inner and outside diameter. So it doesn´t matter if the shaft rotates inside of them or if the bearing itself turns in the housing. In theory.

Keep things spinning – but where?

In reality however, it is not irrelevant, if the plain bearing rotates around the shaft in the housing or if the bearing remains still and the shafts turns inside of it. Usually, shafts are optimized for sliding. Housing holes are not. On the contrary: Most of the time, the machining quality of housing holes is quite cheap. They are simple holes drilled into a piece of metal. Or cut by lasers or stamped. Creating holes with a smooth inner diameter is expensive and the surrounding material of the hole is usually some cheap construction steel or sheet metal. All these circumstances are pretty much a collection of no-nos for wear- or sliding components. And this is why you don´t want your bearing to turn with the shaft in the housing hole. While the bearing itself won´t have a problem running on it´s outer diameter, the surface it will run on will.

In fact, both sliding surfaces in a bearing system are of equal importance. If the metal sliding surface is too rough and abrasive, the bearing will suffer from highly increased wear, resulting in more frequent down times or even damage to the bearing system. And that´s why you will want to go for a classic press-fit non-rotating plain bearing with a rotating shaft inside. And that´s also why you will want to come up with alternative ideas, if you can´t maintain a press-fit.

Free design choice with plastic bearings

Plain bearings made from plastics can be made in almost any shape or form. Limitations known from Metal/PTFE bearings like sheet metal thicknesses or the necessity of lubrication-grooves or lubrication-nippels you would need for bronze bearings don´t exist. On top of that, manufacturing technologies like injection molding, 3D printing, sintering and machining of barstock materials allow you to explore part design with few limitations.

Here are some options of how to do easy anti-rotation features:

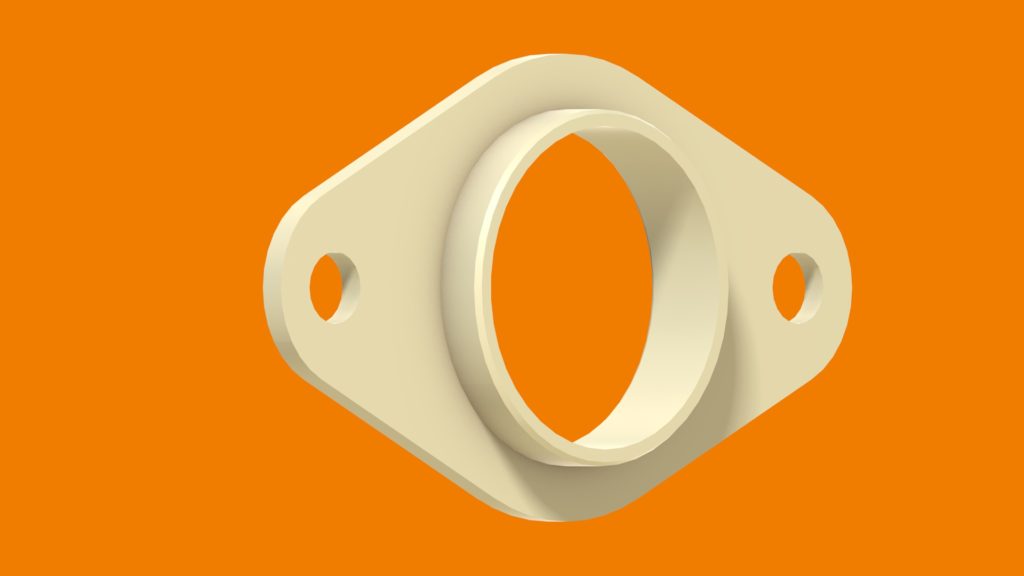

Option 1: Anti-rotation feature with holes in the flange

By drilling holes in the flange (or implementing them from the beginning in the injection mold), simple holes in the flange can serve as an anti-rotation feature. Just put some screws inside and fix the bearing to the housing. Done. For higher quantities, this design is not too great however, since assembly requires manual labor and is therefore more time consuming. On top of that you will need to factor in the costs for screws for each bearing.

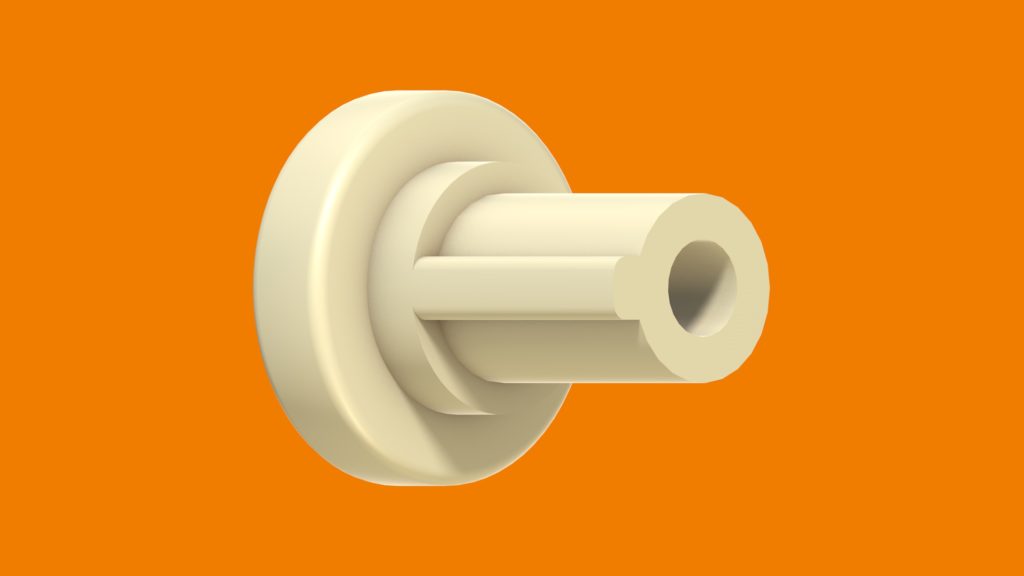

Option 2: Anti-rotation features with simple form-fit on the outer diameter

Even simple measures can be reliable and economic solutions to keep bearings in place. Form-fit means that the bearings shape in itself serves as an anti-rotation feature. You can achieve this easily by changing the round outer shape of a bearing into something with an edge or any other protruding feature. The cost increase for an according injection mold are relatively low. You should however, consider that you will need to have a corresponding shape in the housing hole too. Also, for automated assembly it may be necessary to make sure the bearings are always properly aligned with the housing hole.

Option 3: Machining / treatment of the housing hole

Even though this topic was covered in the beginning of this post already it should be mentioned as a feasible option. Sometimes it can be cheaper to just have another look at the housing hole. Maybe it could be easier to just make a properly tolerated housing hole. Typically a regular H7 tolerated bore is enough. If you want to increase press-fit even further, you can also try to increase the surface roughness of the hole or decrease it´s nominal size a bit Be careful though, as tighter press-fits can lead to creeping in the material from mechanical tension….resulting in less press fit over time.

It doesn´t always have to be “tailor-made”

In the end, it doesn´t always have to be a custom made solution, which usually comes with added costs for custom injection molds or setup costs. Some bearing manufacturers like igus® already have solutions readily available in their catalogs. These are typically available from stock and you can even download their CAD-models to fit them in your design more easily. That way you can cut on purchasing costs but also on time and costs for development and design work.

Finally, there are countless ways to keep plain bearings from moving out or spinning out of control. It depends on your application and it´s environment which solution is the best one. If you need any assistance with that, feel free to contact us at igus®.