How to find the best drive for your igus® linear robot

Adriana Glazer | 27. January 2021

Many bosses want their employees to develop a “drive”. We are already a little further ahead and even sell it … because today, in our series on Cartesian robot/linear robot solutions, we are dealing with the question of what influence the drive versions have on the drive forces. First we will look at the different versions, then we will look at the advantages and disadvantages. If you would like to learn more about linear robots, read on here:

entering the world of automation with igus linear robots

Which drive versions are available?

Basically for understanding: a linear robot consists of at least two axes that can be moved, for example, in the X and Y direction. When we talk about linear robot drives at igus, we are referring in particular to the drive of the X-axis/axes. There are some special features here in particular.

In diagram 2 you can see a room linear robot (3-axis for XYZ) DLE-RG-0003. By the way, our igus linear robot systems can be delivered within 24 hours. More information is available here.

In the red field you will find the motor again. This is connected to the linear axis with the aid of a coupling. The linear axis also has a two-side drive or output pin. This is found in the blue field. The main shaft is connected to this second pin. This ensures parallel synchronous drive of both linear axes. This way, no tilting can occur due to the transverse axis (Y), at least not with light loads. Three couplings are needed for this setup.

In the following video you can see the drive in action (from 0:43 min.).

Single-sided linear robot drive’

For the somewhat tougher cases, there is our linear robot drive solution. In principle, this means that the motor is installed within the two X-axes and drives the main shaft directly.

I recommend that you always select or purchase the drive in consultation with our technical sales department. This way we can ensure that you obtain the correct product.

But back to the topic. What are the technical benefits of the linear robot drive? In addition to the obvious (space-saving, compact design), the linear robot drive reduces the drive force of the X-axes through a more even application of force and less torsion of the main shaft. Thus, in case of doubt, a smaller motor can be selected or even larger and more dynamic loads can be moved than is the case in the lateral version. Three couplings are also needed here.

Linear robot drive central

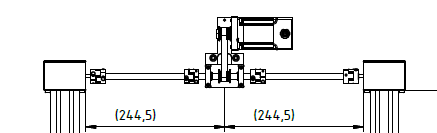

With the centrally arranged linear robot drive, the drive – as the name suggests – is installed exactly centrally between the two X-axes. This ensures exactly uniform force transmission to all drive components.

The main shaft is divided into two elements of equal length. This version is exceptionally suitable if the distance between the X-axes is to be very high. Four couplings are installed in this version.

In summary, one can say: a linear robot drive is advantageous for:

- High loads

- High dynamics

- Large distance of the X-axes (torsion of the main shaft)

- Saving space with small installation space

Now I hope that I have been able to give you an overview of the subject. If you have any further questions, please do not hesitate to contact me.

Markus Ziermann

Project Manager drylin® E electric drive technology

E-mail: mziermann@igus.net

Phone: +49 2203 9649-7201