How the Industrial Internet of Things (IoT) has led to the development of smart plastics

Richard Habering | 23. June 2021

The increasing spread of the Internet of Things is transforming global markets. But while many of the applications that attract the most media attention, such as smart home systems, are in consumer sectors, the biggest effect is expected in industrial settings. More widespread networking is already delivering efficiency and productivity benefits across sectors as diverse as manufacturing, mining, power supply and agriculture.

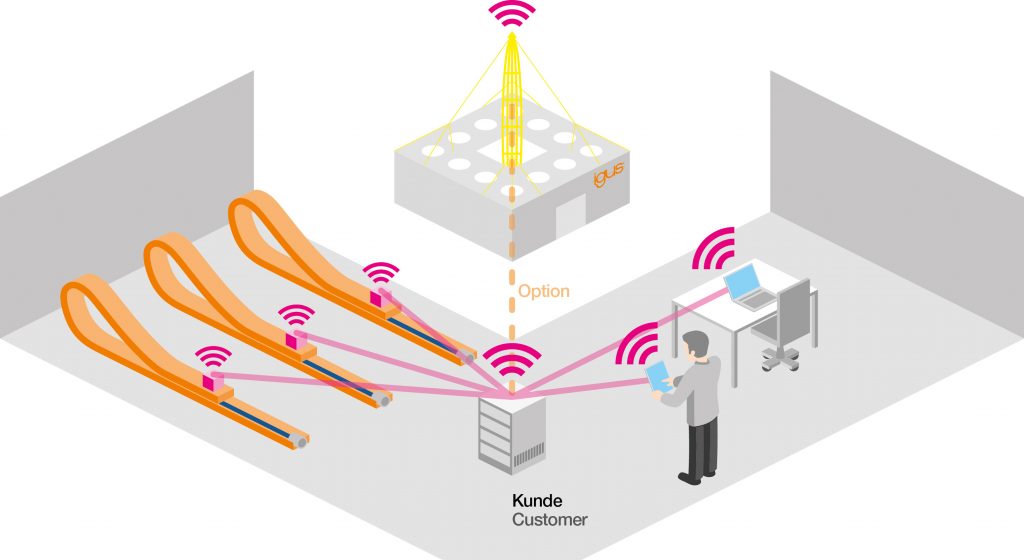

In its first stages, IIoT was limited to high-value, big-ticket technologies such as B. aircraft turbines, for which the enormous costs associated with failure justified the investment. But now there is a discernible trend towards communication-capable, intelligent devices being used to create integrated systems at the lowest level of the automation pyramid. The current development is toward integration of all “factory objects” in a smart factory into networks, and it is expected that every motion plastic component – cables, energy chains and linear plain bearings – will have full communication capability. These components will have sensors that enable them to collect and analyse data, opening up new IIoT-related business models for machinery and system manufacturers across a broad range of industrial sectors.

Predictive maintenance as a game changer that eliminates unplanned downtime

According to research performed by Accenture Technology, a globally active consultancy, the successful implementation of predictive maintenance can have a marked impact on the performance of industrial organisations across sectors, saving up to 12% over scheduled repairs, reducing overall maintenance costs by up to 30% and increasing breakdown avoidance by up to 70%. Accenture cites the example of Thames Water, the largest provider of water and wastewater services in the UK, which is using sensors, analytics, and real-time data to help it anticipate equipment failure and respond more quickly to critical situations such as leaks.

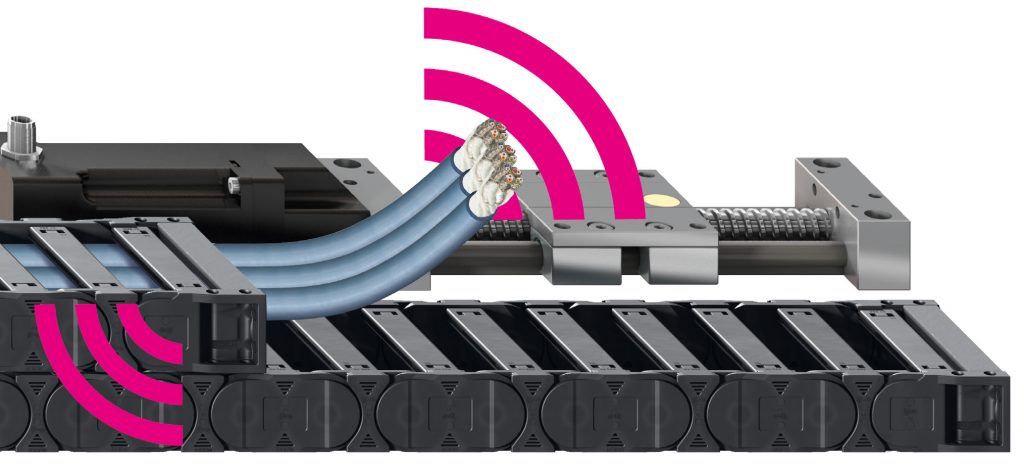

It’s from this context that a new breed of smart plastics has begun to emerge – especially in cables, energy chains and bearings, where intelligence is integrated by adding sensing, monitoring and communication capabilities. Adding such technologies can accurately predict the lifespan of cables used in automated assembly lines, cutting machines, electronics manufacturing, heavy robotics and material handling. Energy chains used in applications such as machine gantries, indoor cranes and water treatment plants can measure their own wear. Smart plastics can deliver Industrial Internet of Things capability, potentially increasing plant availability, maximising service life, and reducing costs with condition monitoring and predictive maintenance methods.

Motion plastics are already being used extensively worldwide in moving applications in industry and everyday life, so a valuable body of performance data is already available. At igus®, a 3,800m² test laboratory helps the company’s engineers to accurately predict product service life, ensuring greater reliability. But smart plastics represent the next step for better-connected “smart factories”, in which automated condition monitoring and predictive maintenance minimise downtime. This helps improve system efficiency and reduce operating costs.

Smart plastics are decisive for the distribution of Industrial Internet of Things infrastructure

There’s no doubt that the Industrial Internet of Things is already driving enormous changes across the manufacturing sector. Sophisticated sensing and data analytics used to be restricted to high-end, big-ticket pieces of equipment like aircraft turbines. But the benefits of IIoT-capable systems are now being capitalised on throughout the industrial landscape, as companies realise the value of having clearer asset visibility. This has prompted the emergence of smart plastics, which are already helping to underpin the general trend towards more networked factories as part of the Industry 4.0 revolution. Because intelligent “factories of the future” are becoming reality, connectivity is being applied in production as never before. The demand for IIoT-capable smart plastics will therefore continue to rise as machine builders and equipment makers look to future-proof their products. This represents a significant business opportunity for engineering component manufacturers, allowing them to offer traditional products with built-in intelligence.