How do I use the igus 3D printing CAD configurators?

Paul Gomer | 20. September 2020

A CAD configurator has many advantages. It shortens tedious recurring design work and saves time and money with simple use and consistent data quality.

Basically, our 3D printing CAD configurators enable a fast implementation of a variant-rich wear-resistant part by determining individually selected and valid product features. Thereby it is very important to configure a data set suitable for production, especially for 3D printing.

Accessible via our CAD configurator overview, you can configure your CAD data for wear-resistant parts online in just 3 steps.

On the basis of a gear configuration, we will explain below the steps required for a successful configuration:

1. Selecting component group

Go to the overview of our 3D CAD configurators and select the component group “Gears”.

The selected igus CAD configurator opens and you can start immediately.

2. Create your individual 3D model

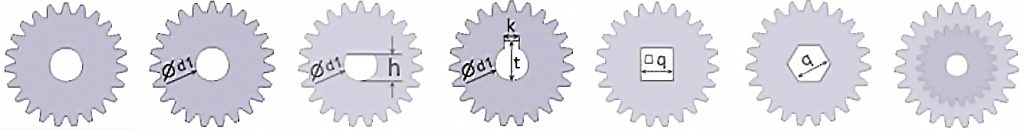

· Select the appropriate template as the basis for your component:

– shape ( hole, flat, square or feather key groove) and

– toothing (single or double toothing)

· Selection of the calculation method: tooth module or tip diameter; missing data: add gear width, step width, hole diameter.

· The 360 degree view of the component is updated according to the dimensions you have entered.

3. Download CAD file or insert it directly into your own CAD software

Select the required file format for the download and then download the CAD file. Click on the orange download button and follow the link to the download centre

– To save individual configuration data on your computer, simply use the save symbol.

– To download all configurations in one zip file please use the orange download icon.

· Alternatively: with direct insertion, you can easily and conveniently insert your configured models into your CAD programme and further process them there. For this the Click2CAD tool box is required.

Other CAD configurations are created in the same way.

If you want to have the configured 3D model produced directly by our 3D printing service, you can upload it via our 3D printing service website. Please make sure that the STEP file format is selected.

Do you have questions or suggestions for improvement regarding our CAD configurators? Just leave a comment here, or leave a personal message for us.

priyanka raval

Your blog got me to learn a lot,thanks for sharing,nice article