Hardness test for the latest P4 generation

Jens Göbel | 24. February 2020

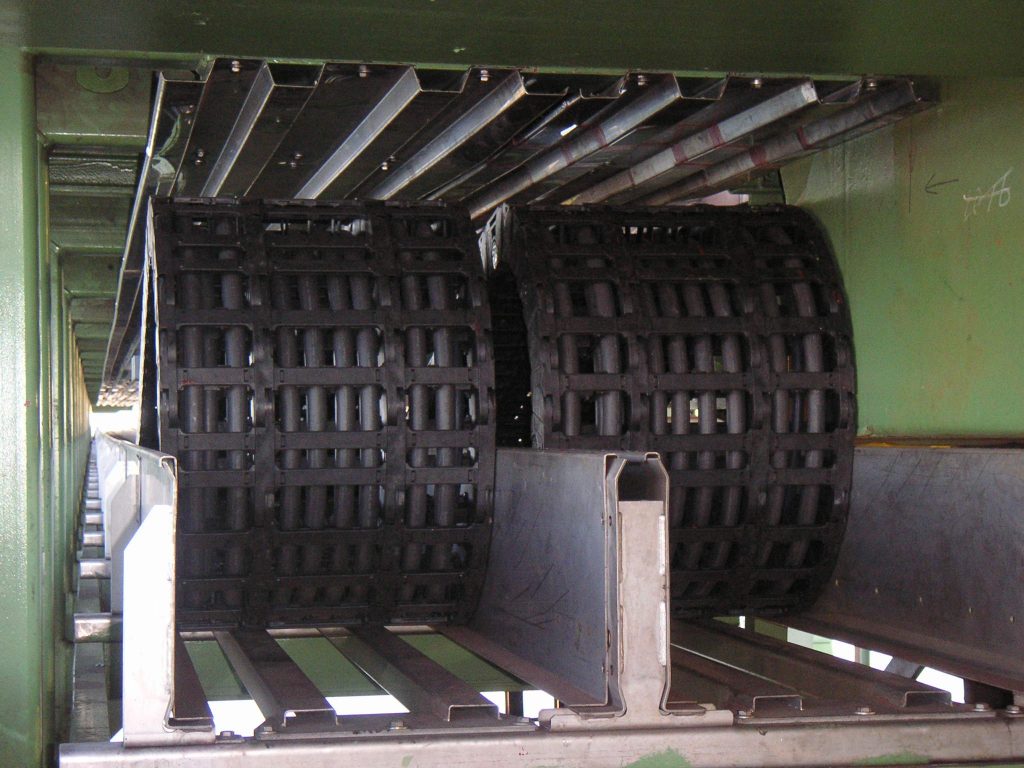

P41.80Ri roller energy chain on ship-to-shore crane at EMO B. V.

With a trolley drive of over 100m, a travel speed of up to 4m/sec and over 50kg/m fill weight, the igus P41.80Ri roller energy chain has already been performing its services on gigantic ship-to-shore cranes at EMO B.V. since the end of 2015. in Rotterdam, one of the largest bulk cargo handling ports in Western Europe. The port is in operation 24 hours a day, seven days a week and so is our P41.80Ri chain, the largest chain in the P4 chain series.

This demanding crane application was specifically selected to thoroughly test the P4.1 with its tribologically optimised iglidur® plain bearings in the pin/bore connection of the chain links to reduce friction. Officially, the P4.1 was not presented to the public before 2018. On the EMO ship-to-shore cranes, the chain has already completed over 9,000 operating hours and has long since proven its advantages.

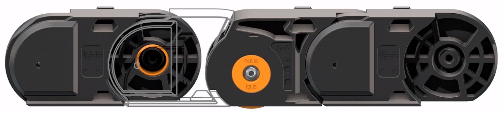

Through our continuous further development, from the individual roller integrated in the chain link and the split P4 roller, up to a P4.1 rol e-chain equipped with a tribo-bearing (optionally available with intelligent service life monitoring – igus® isense), the limits have been pushed back and the service life of the energy chain system has been significantly increased.

Energy chains for cranes from igus®:

The igus® roller energy chain has conquered the dockside crane market with over 1,250 STS energy chain installations (of which over 570 with the P4 chain series) and more than 6,880 RTG and RMG installations worldwide (since 1999). https://www.igus.eu/info/industries-crane-industry