Goliath the Printer: this 3D printer is as big as a room

pwirth | 31. August 2020

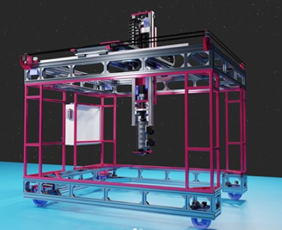

Everything except the small: students Robina and Chris’ 3D printer has a 2 x 2 x 2 metre installation space. We are enthusiastic about the 3D Goliath – and support the young industrial designers with free equipment.

We all know about home 3D printers, compact devices no bigger than a microwave oven that print plastic gadgets – pen holders, whistles and so on. “Smaller 3D printers are widely used and are now a standard in digital manufacturing. We now want to explore what applications are possible with larger 3D printers”, say students Robina Godwyl and Chris Walter, who study industrial design at Burg Giebichstein Kunsthochschule in Halle. In their final semester, they are building the Goliath among 3D printers, almost as big as a room. “Our 3D printer will have a footprint of 2 x 2 x 2 metres. ” Space enough, for example, to manufacture large furniture from plastic.

Challenge: moving energy and data cables with protection

For several weeks now, the students have been fiddling around in the university’s workshops and in a discarded shipping container – similar to Günter Blase in the garage during the founding of igus. However, their product is much larger than an energy chain. The template for the giant 3D printer is a 3D model that the young inventors created with CAD software.

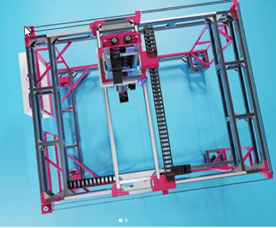

With this design in hand, the inventors first welded a rectangular metal frame, the supporting body of the printer. There is a frame made of aluminium profile sitting on the rack. A carriage moves horizontally along the x-axis. The carriage in turn has two parallel running struts on which the print head frame moves vertically along the y-axis. Via a linear unit, the print head finally moves along the z-axis from top to bottom. It can therefore reach any position in the installation space via these three axes.

A mobility, however, which presented the designers with a challenge: if the print head moves along the xyz axes, power and data cables must follow in a controlled movement. If the cables were to hang unguided on the print head frame, there would be a constant danger of collisions, cable breaks and system failures. In order to guarantee a high level of system safety, Robina and Chris therefore set out to find a professional energy supply system.

igus supports industrial designers with energy chains and cables

The industrial designers found what they were looking for at igus. As a company that offers 3D printing services, we were immediately impressed by their research. We therefore provided the tinkerers with free material for their research work. Amongst others, cables of the chainflex series that are designed for permanent movement – control cables (CF130.25.03.UL and CF2.02.18) and motor cables (CF330.60.01.D). For the safe guidance of these cables, Series 2400 energy chains are used. This is a medium-sized, strong system with an inner height of 25mm. The e-chains enable hanging applications of up to 40m, unsupported lengths of up to 2.25m and a fill weight of up to 4.8kg/m. They guarantee low-friction, dry operation without lubricating oil and are virtually maintenance-free.

Robina and Chris have already installed the e-chains in the 3D printer. They follow the aluminium profile along the x-axis, the movement of the print head frame along the y-axis and the movement of the print head along the z-axis. The energy and data cables are fixed in such a way that they fold and unfold in a controlled manner during movements. Cable breaks are almost impossible. igus guarantees a service life of up to 10 million double strokes. After initial trials, industrial designers are confident that the technology will provide reliable cable guidance and improved 3D printing. Keep it up!

Please contact us.

Are you looking for maintenance-free and low-wear energy supply and cables? You will certainly find what you are looking for on the following page. igus.eu/e-chains/energychains?L=en