Flanged bearing – what you need to think about

Lars Butenschön | 6. May 2022

In order to fix plain bearings in the receiving bore so that they are form-fitting, a collar or flange is attached on one side or, in some designs, both sides. If you use flanged bushings in your application, some design considerations will help avoid bearing damage.

The housing hole

The housing hole should be perpendicular to the component surface. Otherwise, the bushing flange will not lie flat on the surface. The flange can then deform or even break, depending on material, either during assembly or under mechanical stress from the application.

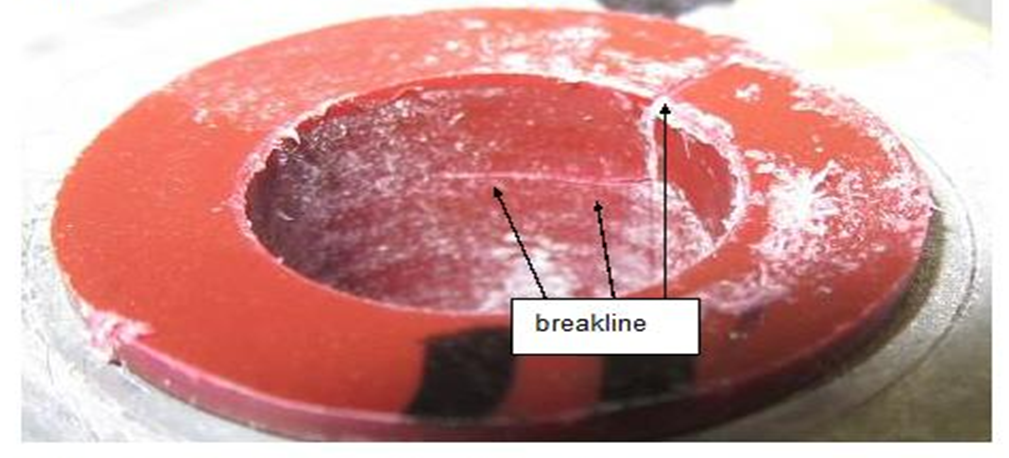

The hole should also be free of burrs and ideally provided with a chamfer. A relatively small chamfer is sufficient. Chamfers that are too large can impair flange or bushing load capacity along the running surface.

It is imperative that burrs along the edge of the hole be avoided. Even with correctly executed chamfers and vertically drilled holes, trapped burrs can lead to undesired dimensional changes or even damage the bushing.

The load

Edge loads as a result of introduced torsional or tilting moments can lead to disadvantageous stresses on the plain bearing. Shear forces can arise between the collar and the cylindrical body of the bearing and lead to separation of the flange and thus to axial displacement of the plain bearing out of the housing hole.

These edge loads often result from insufficient self-aligning when a number of bearing points are arranged in sequence. Tolerances and dimensional deviations cause alignment errors which then result in edge loads on the plain bearing.

Torques can also act on the plain bearings in corresponding application scenarios if the load is applied outside the bearing’s centre of gravity. Additional support can help.

If all else fails, uncouple

If the housing hole is still not designed differently, or torsional or tilting moments cannot be adequately absorbed, consider a two-component solution. Instead of a flanged bushing, use a simple cylindrical bushing with an additional thrust washer for axial support. The components thus absorb the necessary forces independently of one another. But this solution also has disadvantages that need to be considered. Multi-component solutions require more elaborate assembly and often cost slightly more.

We would be happy to assist you!

We support you in designing your bearing point, from selecting the right shape and most suitable production process to the subsequent implementation and delivery. Please contact us!