Fire protection in the aircraft – what is behind FAR 25.853?

Florian Schiller | 3. March 2021

A fire on board an aircraft is one of the most serious events that can happen when flying. Fire and smoke can spread rapidly in a cramped cabin and cause harm to passengers. Since the safety of the guests is paramount when flying, one wants to avoid fires at all costs.

That is why all materials used in and on the aircraft are subjected to extensive FST tests. FST stands for Fire, Smoke and Toxicity – i.e. flammability, smoke intensity and combustion toxicity.

All materials must pass the vertical fire test (FAR 25.853) described below to demonstrate flammability. The actual place of use also determines whether only the flammability is checked or the entire FST test is carried out. See also the table at the bottom of the page.

Which igus materials are certified?

In contrast to standard available plastics, such as PEEK or PA, iglidur® materials from igus® are specially formulated high-performance polymers for moving applications. This means that iglidur® plastics always consist of a base polymer, solid lubricants (to achieve particularly good tribological properties) and certain additives, depending on the application.

In order to also meet the high requirements regarding fire protection and flammability of the aerospace industry, igus® has developed various materials with flame-retardant additives and had them certified. The three standard materials iglidur® X, J350 and A350 as well as iglidur® H and G V0 meet the requirements of the FAA. The plain bearing materials have been tested by an independent test institute in accordance with the fire test method FAR 25.853 App F, Part 1a 1(ii) with positive results.

Who lays down the rules?

Fire safety requirements are precisely defined by various authorities worldwide. In order to be used in an aircraft interior, all materials must pass fire tests.

In the USA, the regulations are set by the Federal Aviation Administration (FAA). The associated document is called FAR (Federal Aviation Regulation).

In Europe on the other hand, EASA (European Aviation Safety Agency) sets the rules and has drafted the CS (Certification Specifications) and the JAR (European equivalent to the FAR) for this purpose.

The FAR, JAR and CS are largely the same in terms of content. In all three regulations, “Section 25” lays down the rules for large commercial aircraft and “Paragraph 853” concretises it again for all materials in the aircraft interior. The standards of fire testing for the interior of the aircraft, which are identical in content, are thus described in the regulations FAR 25.853, JAR 25.853 and CS 25.853.

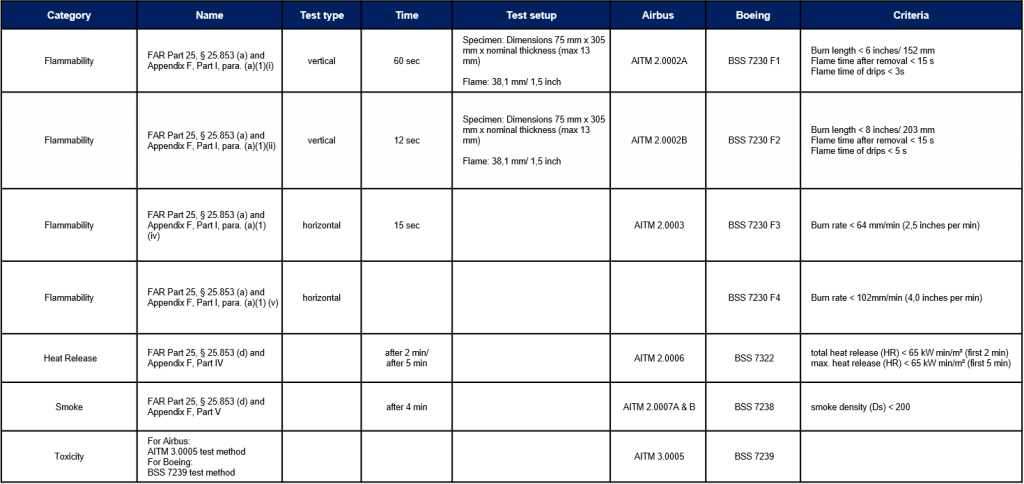

In addition to these authorities, the two largest aircraft manufacturers – Airbus and Boeing – have also produced internal documents defining safety regulations. The AITM (Airbus Industrial Test Method) from Airbus and the BSS (Boeing Safety Standard) from Boeing. In terms of content, these are identical to the previously mentioned regulations on fire protection from FAR and JAR.

How do the tests proceed?

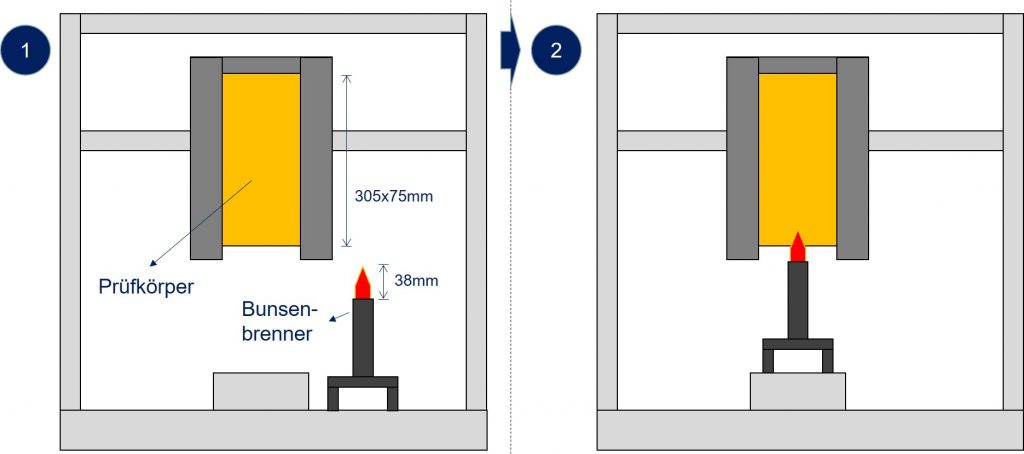

The tests for FAR 25.853 are conducted in a standardised 12-second or 60-second vertical fire test:

The test takes place in a test chamber in which the test specimen is installed vertically. The test specimen must comply with the dimensions 75mm x 305mm x nominal thickness (max. 13mm). The centre of the lower edge of the sample is exposed to a gas flame for 12 or 60 seconds, depending on the type of test. The flame has a defined height of 38mm. During the test, notes are taken for the afterflame time, burn length and flame time of drop.

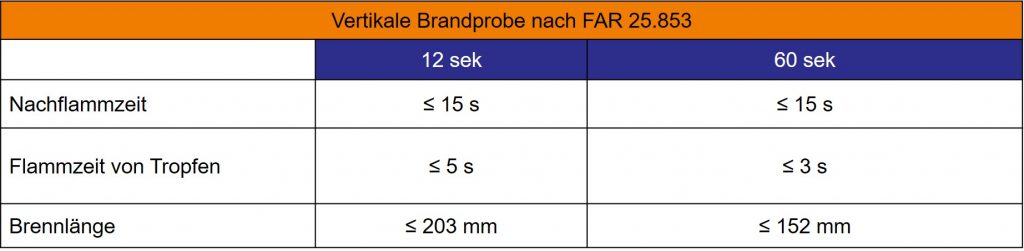

In order to pass the vertical fire test with 12 or 60 seconds flame exposure time, the following criteria must be met.

| Afterflame time | Flame time of the test specimen after removing the Bunsen burner |

| Flame time of drops | Flame time of the parts dripped from the test specimen |

| Burning length | Length that the test specimen has burned during the period of exposure to flame |

The 60-second vertical fire test is applied to materials used in assemblies such as ceilings, wall panels, partitions, on-board kitchen fittings, large cupboards or luggage compartments. igus® products are mostly found in this category.

The 12-second vertical fire test, on the other hand, is used for assemblies such as floor coverings, seat cushions, upholstery, coated fabrics, leather, electrical cable, joint and edge coverings and several more.

Summary and relation to Boeing and Airbus standards

The following table summarises the different test methods. In addition, the link between the test methods of FAR 25.853, AITM and BSS is established.

Michael Tripp

Is there any specification regarding air flow through the chamber during testing? Industrial Hygiene concern during testing with potential exposure to smoke fumes.

Rob

You have the 12 and 60 sec test categories backwards. Seat cushion assemblies, floor coverings, edge trim, single materials, etc are 12 second vertical tests. Assemblies for Cabinet structure, partitions, etc are 60 second tests.

Shobitha

Hi,

Can we get more details on how these values are fixed?

Burn length <8 inch, Flame time after removal <15 seconds. Why not 9 inches or 100 seconds odd?

Florian Schiller

Hi Shobitha,

these values are defined by the FAA. Their focus is always on the safety of the passengers in the airplane.

So, I suppose, that these are values which guarantee, that there is no danger of a fire in the aircraft cabin.

I hope this was helpful to you?

Best regards,

Florian