Energy chains or motorised cable drum?

Marco Thull | 17. March 2020

Energy chain or motorised cable drum: which energy supply system comes out ahead? Probably there is no blanket answer here because, in the industrial world, no two applications have exactly the same conditions.

When do we consider a cable drum and when a motorised cable drum?

Motor and spring cable drums have been developed for the power supply of moving consumer loads. Motor or spring cable drums are required, depending on the travel and the power required by the end user.

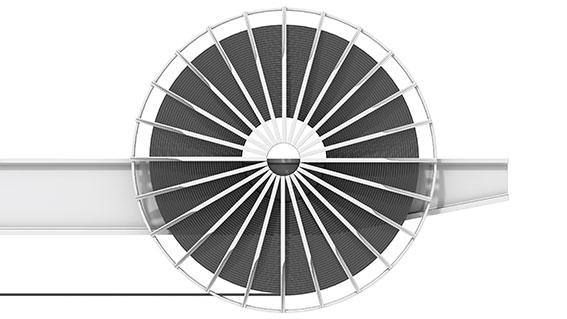

Cable drums with motor drive are called motorised cable drums. They usually consist of a drum shell, drive and slip ring transmitter.

What exactly is an energy chain?

The energy chain (also e-chain) is a component in mechanical engineering that guides and protects highly flexible cables, pneumatic or hydraulic cables. The cables are connected to an end consumer (machine) that is constantly being moved back and forth. Without such a guide, the cables would not be able to withstand the continuous load for long and machine failures would be pre-programmed. Energy chains are very modular and can transfer energy, data, air and fluids in one system.

Motorised cable drum or energy chain?

Different elements are weighted differently. Some points favour the motorised cable drum – among these are its simple assembly. Others are for the energy chain, such as the cable protection, the largely maintenance-free operation and the extendibility.

Which energy supply system is the most efficient?

Whenever design engineers have to guide hoses and power and data cables in moving applications with long travels (more than 100 metres), the following question arises: which energy supply system is the most efficient, especially considering such factors as reliability, maintainability and future security? A motorised cable drum? Or an energy chain?

Learn more about the advantages and disadvantages of both systems in this free white paper:

Read also energy chains vs. festooning systems