Energy chains or festooning systems?

Marco Thull | 18. March 2020

Reliable and dynamic cable management is one of the greatest challenges in modern crane technology. Virtually all modes of crane applications are facing intensifying requirements

regarding travel distances, speeds and precision. In the international overhead crane market where various standards come into play, manufacturers and end-users seek electrification solutions that can be adapted to the respective scenario. So does the choice fall more on an energy chain or festooning system?

Power supply options

While the components must be modular, they should also be consistently easy to install, low maintenance and cost-effective. Engineers often turn to two power supply variants to try and meet these demands: festooning systems and energy chains.

Festooning systems

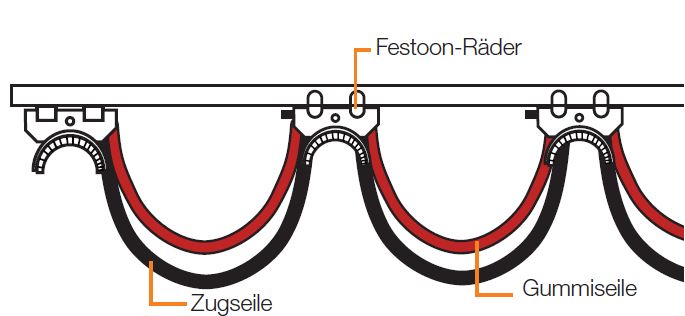

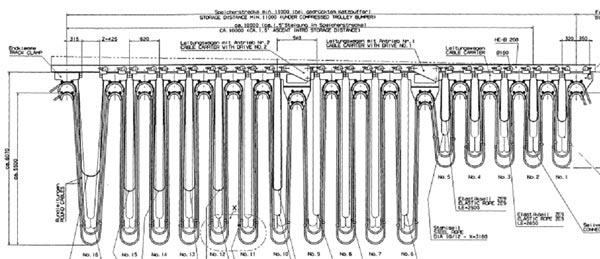

Festooning systems are designed to provide direct electrification with flat or round cables. The cables in festoons are hung from trolleys that stack together at the end of the crane rail. Whilst this structure provides defined linear guidance, it consumes space on the crane rail, limiting the amount of crane travel that can be accomplished in a given dimensional window. As the cables are essentially clamped in bunches, it makes replacement or addition of cables a time-consuming process. The festoon design also incorporates a variety of linked components, including wheels, tow cables, shock cords and bearings. Each individual part requires regular maintenance and lubrication, especially when exposed to rough operating environments.

approx. 3,000mm length for the “cable loops”

approx. 800mm system height, approx. 10% less steel construction (for the cable station)

The principle of festooning systems

In festooning systems, cables and hoses hang loose whilst guided. Unprotected, the cables can swing, become tangled and get caught in the crane structure, especially during harsh weather, which leads to costly repairs. Often, festoons use flat composite cables consisting of multiple conductors in a single jacket. When these cables are used, the entire composite cable may need to be replaced if one conductor becomes damaged. For instance, ship to shore cranes are often found to be equipped with festooning systems. As this application environment is exposed to high winds, heavy rain, ice and other barriers, festoon users face high costs for repairs caused by wear and weather. This means further downtime wasted on maintenance and inspections. The hanging cables and steel-dominated structure of festoons also requires ample space for setup.

Avoidance of maintenance and costs

To avoid the maintenance and costs that come with festoons, users are increasingly using an alternative electrification system—the energy chain. Thanks to its corrosion-free and wear-resistant specifications, it is able to withstand the demanding operating environments of the high-performance polymer e-chain, yet has a simple design and is very easy to install.

Efficiency of the energy chain

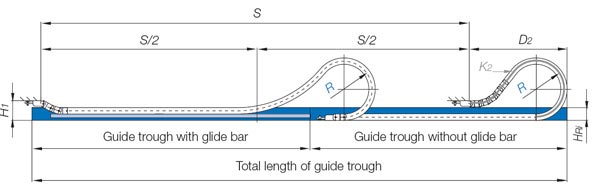

The energy chain is designed for optimal efficiency. Cables are securely guided in the system with interior separators, so cables can never cross over one another and become tangled. For strain relief, cables are tightly clamped and can be easily and individually released for repair or replacement. While in festooning systems an entire composite cable may need to be replaced if one conductor is damaged, with e-chains, only the one damaged cable would have to be swapped. Since the e-chain does not require a loop parking station, a centre mounted e-chain system requires approximately 50 per cent less cable than a festooning system. This considerably reduces mechanical stress, system weight and acquisition costs. With no hanging loops, the required operating window is also considerably less than festooning systems, noteworthy for applications with restricted space.

Easy assembly

Installation is truly simplified with the e-chain; a guide trough is installed on the crane girder, and the e-chain is filled with cables and then installed in the trough. The moving end is attached to the trolley and the cables are led to their connection points. The e-chains can already be filled with cables by the energy chain manufacturer, making installation even more straightforward. Horizontal, vertical, rotary and three-dimensional movements can also be achieved. While festoon wheels, shock cords and bearings are marked for wear and require replacement or lubrication, the chains are maintenance-free, only needing basic visual inspections to ensure the system is in good working order.

The e-chains guide and protect

The e-chain® is engineered to protect cables from debris and extreme weather conditions. Due to the clean and durable design, the e-chain is proven to withstand the most demanding environments. Wind is no match for the system, as cables are securely guided and cannot get caught at any point. The predefined bend radius also prevents the cables from being bent below the manufacturer’s recommended bend radius, which sometimes occurs with free-hanging festoons. For additional protection, the chains are available with integrated rollers for extremely long travel distances, as well as special materials for chemical resistance. The rugged energy chain can be configured in many different ways, from use on hoist trolleys at high speeds to managing long runway travels with special requirements. This modularity can be applied to a wide variety of applications, including both outdoor gantry cranes and indoor bridge cranes.

More information

Read more about festooning vs. energy chains on our website or watch the reference video (in English). Further examples of plant modernisation can be found here.

Read also energy chains vs. motorised cable drums