Energy chains on indoor cranes under rough conditions – how resilient are polymer chains?

Jens Göbel | 18. April 2020

As versatile as the various indoor crane designs are, their areas of application are just as varied. Not every indoor crane runs in a clean workshop without heat, humidity, cold, dust and dirt.

For use under harsh environmental conditions, crane bridges are usually developed specifically adapted to the application and operating conditions. Only components that can withstand these conditions are used on such crane systems. A safe and reliable power supply for crane and trolley drive must be guaranteed even under difficult ambient conditions.

Energy chain advantages:

The advantages of the energy chain over other cable or power supply systems are particularly evident under adverse operating conditions.

- low maintenance – no additional drives necessary for the chain system

- Corrosion-free and wear-resistant (e.g. chemical-resistant special material)

- Resistant to heat, moisture and dirt

- Long-term temperature resistance from -40°C to +120°C (short-term up to +180°C)

- High travel speeds (300m/min. and more)

- Version with integrated skate wheels possible (E4/4RHD)

- Compact and space-saving

- Guidance of different media in one system (energy, data, fibre optic cables, gases and liquids)

Heavy-duty chains:

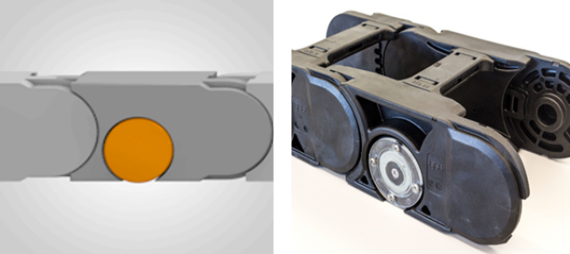

The heavy-duty energy chain series was developed especially for use under rough conditions. This energy chain series is characterised by stable side parts, a robust pin-bore connection (the connection of the individual chain links with each other) and a high torsional rigidity. A larger sliding surface also ensures a longer service life.

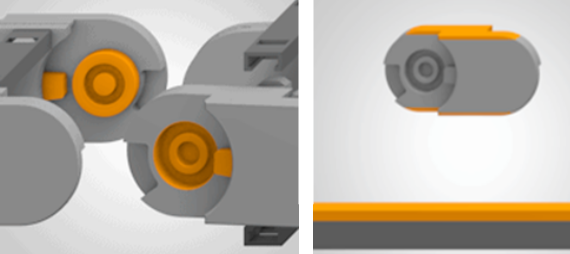

Heavy-duty rol e-chain®:

Alternatively, the heavy-duty series can also be extended by chain links with an integrated skate wheel. The roller chain design reduces the pull/push forces required to move the chain system. At the same time the wear of the energy chain is significantly reduced and the service life is increased.

Cables suitable for energy chains:

Cables suitable for energy chains, such as chainflex ensure that the cable package also meets the requirements of the crane system. From motor cables, control and data cables up to fibre optic cables, the chainflex cable range offers a wide choice.

Examples of heavy duty applications:

Read here an article about applications of heavy-duty energy chains in steelworks: “Heavy Duty” for English steelworks.

If you are interested in energy chains on an indoor crane in a hot rolling mill, then you will find the right article here.

Or watch a video about the use of heavy-duty energy chains for a trolley drive on an indoor crane in the waste bunker.

On our website you will find further examples and solutions for cable guidance on indoor cranes, as well as our brochure for free download.

Do you still have questions or an application you would like to discuss with us? Arrange a virtual consultation appointment now