Energy chains in the work area

mkogelmann | 30. June 2020

Energy chains in the work area

What used to be normal (energy chains in the working area) is now largely avoided. However, some applications cannot be implemented otherwise. Hot or sharp-edged swarf can quickly impair the function of an energy supply system. Regardless of whether the swarf damages the cables or swarf clusters minimise the mobility of the e-chain! To avoid this, closed energy tubes are used instead of open energy chains.

What solutions do modern energy tubes offer?

Accessibility, ease of installation and service

Today, modern e-tubes offer the same ease of installation and service as open energy chains. Depending on the design, e-tubes are openable along the inner and/or outer radius. The guidance of the cables and hoses can be individually designed with suitable interior separation components.

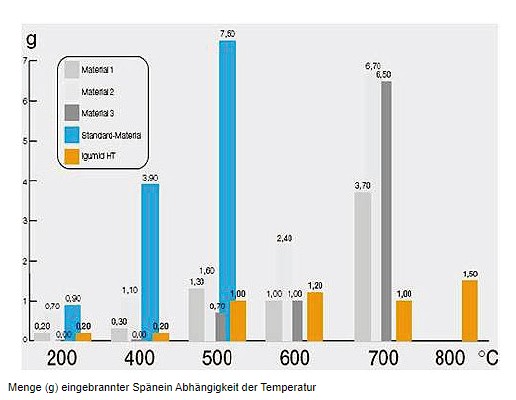

Dry machining – hot swarf

During dry machining, the swarf can reach very high temperatures. Small and short swarf cool down quickly and cannot burn into the plastic of the e-tube. Large swarf on the other hand does not cool down so quickly. Their high temperatures can damage the plastic energy tubes. But modern energy chains also offer solutions here. Tubes made of high temperature-resistant materials can be produced. Thanks to the special material, hot swarf up to 850°C cannot adhere or even penetrate the material.

RX series, the ultra sealed energy tube

The machining of short-chipping materials, such as brass, places particularly high demands on the e-tube in terms of tightness. In order to meet these requirements, the RX energy tubes have particularly smooth contours and are manufactured to particularly tight tolerances. The convex surface allows the swarf to slide off easily.