Energy chain: steel or plastic?

pwirth | 26. March 2020

For historical reasons, energy chains have so far always been manufactured from steel or plastic. Steel has the advantage of allowing longer unsupported lengths. A plastic energy chain has various advantages, including lower cost and faster installation.

There is now a new product: the hybrid steel-plastic chain. The energy chain is built with steel inner links and plastic outer links. Chains made completely of steel are heavier, which negatively affects the fill weight, influencing adherence to European standards.

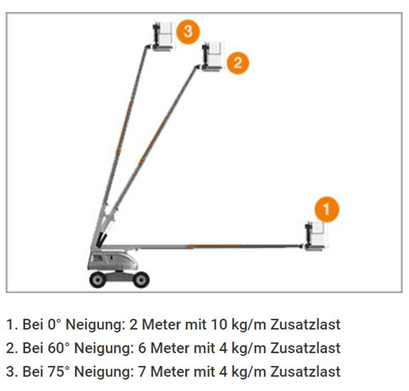

igus has so far focused on manufacturing energy chains from polymer. This area has developed well, since the advantages mentioned above are in great demand. The development of the new YE hybrid chain was focused on cherry pickers, or mobile lifting platforms that can be extended at various angles of inclination. Angle of inclination, fill weight and length of the energy chain are directly proportional. The differences among the various work platforms are described here.

Cherry pickers are in operation in temperatures ranging from -20°C to +50°C all over the world. There are other requirements of energy chains, one being dirt. Systems must also withstand long unsupported lengths. It must also be possible to replace the energy chain systems quickly when maintenance is carried out. As a rule, users perform only an annual visual inspection.

The hybrid chain is 50% lighter than steel-only energy chains and has an unsupported length of up to seven metres (50% more than plastic-only e-chains of the same size). The test photo is included.

What was surprising about the YE test was that the plastic outer chain links’ quadruple plastic stop system was not the weak point. Unexpectedly, it was the steel inner chain links that bent in the load test.

Get the data sheet for the hybrid chain here.