drylin linear robot: introduction to the world of automation

Adriana Glazer | 24. April 2020

In short, linear robots are multi-axis systems that are (usually) constructed to move to Cartesian coordinates. One synonym for linear robot is Cartesian robot. But what do linear robots look like, and why are they seen as the gateway to the world of automation?

Linear robots from igus: part of the linear technology modular system for infinite varieties of application

“We need a linear robot for this application.” When I heard this term for the first time, I was just starting out at igus, and I had no idea what it meant. What was it? Why “linear”? Why “robot”? Or is it an igus product? “Quite likely”, I thought, and entered the world of igus linear technology.

igus linear technology provides one of the large product ranges – we give a solution to almost any problem. Sometimes, I think that we have reached a point where we can do so much that we don’t even know how much we can do. Does that make sense? I hope so: from individual shafts and linear plain bearings to profiles, carriages, and driven axes (manual or by machine) to multi-axis kinematics and delta robots, we offer a modular system that prompts creative dreaming.

Some possible applications are as follows:

- Applying glue beads to assemblies

- Welding point setting

- Performing typical pick-and-place tasks

- And many, many more.

At igus, we make a basic distinction among three primary types of (multi-axis) linear robots:

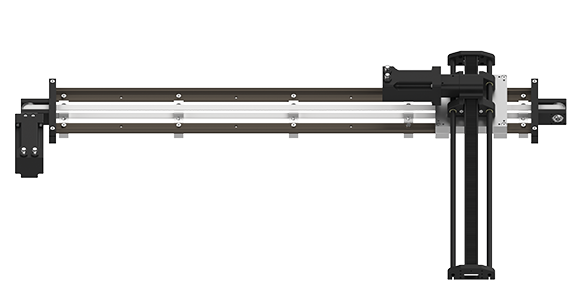

Line robots

The line robot consists of two axes: X and Z. This allows the implementation of applications that work perpendicular to the working plane and travel horizontally. An example is sorting systems that pick bad parts from the conveyor belt.

More information is available here.

Flat linear robots

The low-profile linear robot for X-Y movements to reach predefined surfaces. Typical application examples are automatic measuring and testing equipment.

More information is available here.

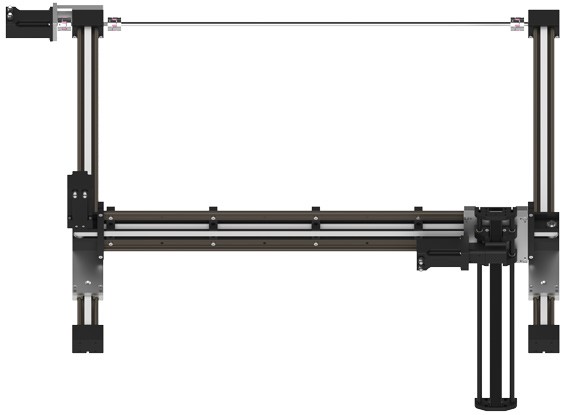

Room linear robots

Three-dimensional solutions are feasible with the room linear robot. The system is based on a low-profile linear robot with the associated cantilever axis. This means that it allows movement in the X-Y-Z directions.

More information is available here.

Compatibility for simple configuration and programming

Of course these linear robots’ stroke lengths, motor technology, cables, proximity switches, etc. can also be configured. Optionally, energy chains can be connected. Best of all, you don’t need to be an IT specialist to program a linear robot. Use our igus Robot Control system with free-of-charge software – it’s easy. If you need a bit more flexibility, use our D1 control system.

My summary of igus linear robots

igus linear robots allow implementation of a wide range of applications, but we should always remember that we are in the low-cost segment. Repeatability of 0.5mm is about the best that we can achieve with a three-axis system, but our products are uncomplicated and resistant to dirt. So, if you want to design a machine tool, use our products in the tool changer, not in the machine bed.

Finally, I would like to say that I have come to the conclusion that our igus linear robots offer a lot. Open the doors to your initial automation solutions.

Feel free to contact me. I would be happy to help.

About the author:

Markus Ziermann

drylin E electric drive technology Project Manager

Phone: +49 2203 9649 – 7201