Despite the harsh environment: this energy chain operated for 18 years

pwirth | 9. November 2020

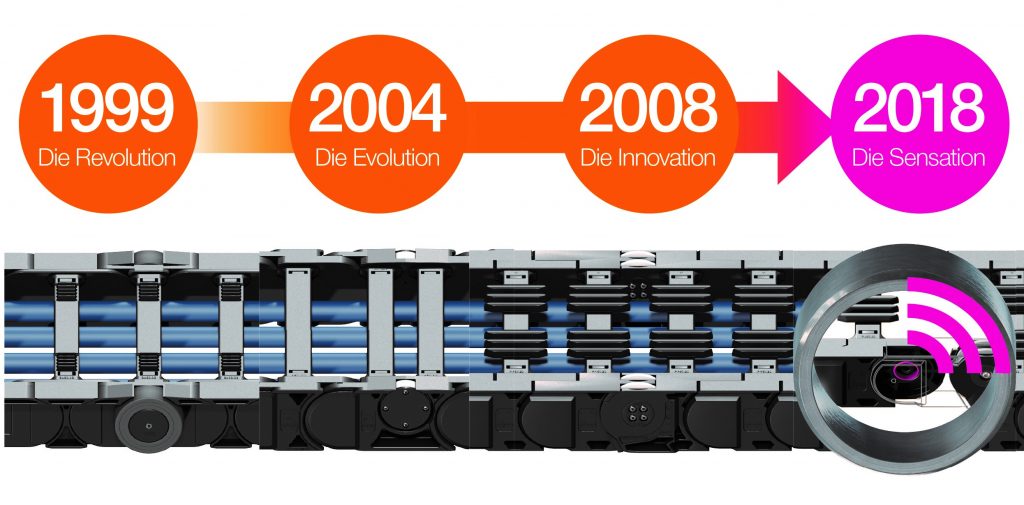

We are not surprised, but nevertheless excited about the news from a customer in the pipe manufacturing industry: for 18 years a first generation rol e-chain has been providing reliable service there – in harsh environments. Newer systems will surpass this record.

What happens in 18 years?: a child is born, learns to walk, graduates from school and after 6,575 days – that is 157,800 hours – comes of age. And the proud parents were always at his/her side. The same is true for engineers who observe their new product on the market. In our case: the rol E400R e-chain, which we developed over 20 years ago. Would the material be able to cope in harsh environments? To prove itself in the long run? Yes, shown by a customer who used the power and data cables of a machine with the E400R in his pipe production facility. The unsupported rol e-chain was in use there for 18 years.

The secret of longevity: rolling instead of gliding

Reduce the coefficient of friction, minimise wear and maximise service life: that was our goal when we developed the E400R. To achieve high robustness and wear resistance, our designers decided to modify the design of conventional energy chains. Whereas it was previously common for the upper run to glide on the lower run when folding the energy chain, this movement should be a rolling one in future. To achieve this, the experts inserted rollers in the chain links of the energy chain, which enormously reduced the coefficient of friction compared to a gliding movement.

A design that pays off especially for long travels, for example, in crane systems. The upper run can unwind over a length of up to 800 metres on the lower run at a speed of up to six metres per second. A gliding movement would require large forces to overcome the frictional resistance. Thanks to the rollers, the plant operator can reduce the drive power for moving the energy chain by around 25 per cent.

In 2004, design engineers double the service life

The first generation of rol e-chain has lasted for 18 years in the pipe factory. How long will the new systems last? For several years. After all, the design engineers have always come up with innovations over the years. In 2004, experts succeeded in doubling the service life of the heavy-duty extension level for high additional loads (4040RHD) compared to the previous series by increasing the pin and hole connections by 100% and the stop surfaces by more than 30%. The e-chain is now a standard for STS cranes and ship unloaders/loaders with long travels and high speeds.

In 2008, the tinkerers then lowered the polygon effect in the rol e-chains of the third generation (P4) by equally dividing standard links and roller links. And rely on a double-roller design that reduces noise and vibration. The rol e-chains are used for applications with very high speeds (< 240m/min) and in plant where noise pollution is a concern.

2018: tribo-polymer plain bearings and sensor technology triple service life

In 2018, the engineers finally provided the latest extension level, the P4.1, with maintenance-free tribo-polymer plain bearings. This increases the maximum speed to over 300m/min. In the course of Industry 4.0 it is also possible to equip the bearings with wear sensors. At a defined wear limit, the sensors send a signal to the igus icom communication module so that the user initiates maintenance in good time. Thanks to these design tricks, the service life of the rol e-chain has tripled compared to the first generation. The energy chain in pipe production could run for 54 years. More than half a human life.

More information and data sheets about the evolution of the rol e-chain can be found under the following link. https://www.igus.eu/info/rol-echain-evolution?L=en