Designing more cost-effectively with E4.1L

Michael Hornung | 23. April 2020

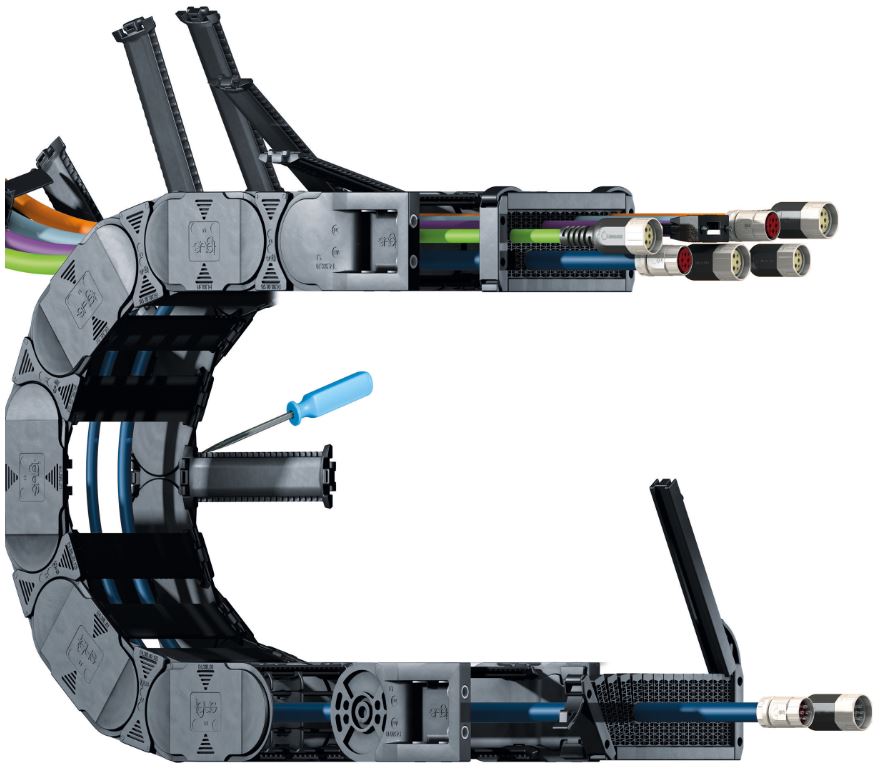

Especially in machine tools, many electrical cables and hoses run through the energy chain. Hoses for hydraulics and cooling with large diameters are often necessary to meet the requirements of flow rates. This means that designers must select energy chains with a large interior space.

Short travels in machine tools are often the rule

Usually the travels in machine tools are no longer than two to three metres. This means that the requirements for unsupported lengths of the e-chain are rather low.

High stability is not always necessary

However, energy chains with a large interior space are often very stable so that they can also be used in applications with longer travels. These then also require a larger installation space there. This requirement is not necessary for the short travels in machine tools. The aim is to design with as little installation space as possible in order to keep the floor space of the machine as small as possible.

Optimisations in the energy chain

So why not simply optimise the side parts of the e-chain and/or the crossbars? We keep the usable interior space or even enlarge it, in the best case we can even reduce the outer dimensions.

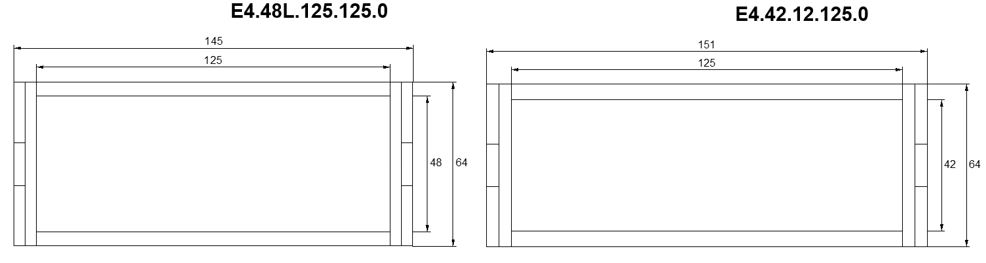

We compare the usable interior and the outer dimensions of these two e-chains with each other. It can be seen that the interior of the E4.48L is 14% larger, but the total area is 4% smaller than that of the E4.42. The permissible fill weight for the E4.48L with a travel of 3m is around 15kg/m, which is sufficient in most cases. So there is nothing against using the optimised version here.

Additional side effects

There are also welcome side effects of these optimisation measures. The energy chains have a slimmer design. They are lighter than the comparable types, which also benefits the machine dynamics. And the energy chains are also even more cost-effective. For an energy chain, 20% or more of the costs can be saved very quickly.

Many selection options available

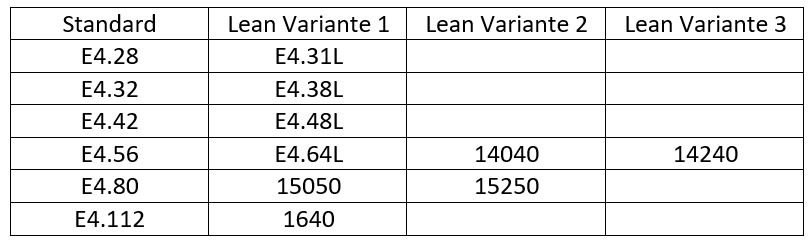

In the E4 series there are one or even several such LEAN variants for almost every type.

Selection options

With the Lean variants there is also the possibility of using enclosed energy chains, i.e. e-tubes. A wide range of accessories such as various interior separation components, mounting brackets and strain relief options are also available for these series.