Corrosion protection with stainless steel in the food industry

Lars Braun | 24. April 2020

What is Kolsterising?

Everyone knows that food and beverage machines require lots of care.

Systems must be cleaned several times a day and disinfected with hot and cold water, foamed with disinfectant foam, cleaned with lye, and disinfected with hydrogen peroxide – the full treatment.

… the corrosion protection that conventional, hardenable stainless steels provide is still not enough.

A vicious circle!

We need the corrosion resistance of stainless steel (1.4305, for instance), but the material cannot be hardened.

At the same time, a hardness of X90 (1.4112) with HRC 60 is needed, but the material is not sufficiently corrosion-resistant.

Is Kolsterising the solution?

The term “kolsterising” can be traced back to a surface-hardening method based on the incorporation of carbon into steel. The hardening process is used with austenitic stainless steels. Kolsterising involves large quantities of carbon being diffused into steel at low temperatures (< 300°C). As an alloy element, the carbon enhances the internal hardness and ductility of the austenitic stainless steel. Kolsterising increases stainless steel’s wear resistance without reducing its corrosion resistance.

Interaction between iglidur materials and Kolsterised surfaces in the food and packaging industries

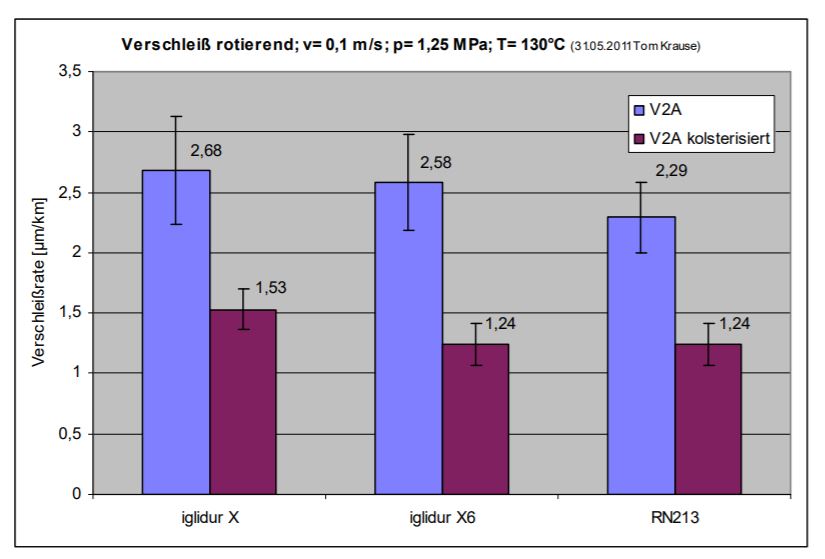

igus has looked deeply into this process and analysed the tribological aspects of the interaction between iglidur plain bearings and these surfaces. A wide variety of tribological tests have been performed with conventional and Kolsterised stainless steels in the igus laboratory.

You can find out more in the “Kolsterising and tribo-polymers” white paper

- Kolsterising: corrosion-resistant surface hardening

- Kolsterising in action for different steel grades

- New design options in the packaging industry

- Interaction of igus plain bearings with Kolsterised stainless steels

- Wear tests on polymer bearings used with Kolsterised and non-Kolsterised shafts