Correctly select piston rings

Lars Butenschön | 12. November 2021

As with most machine components, the devil is in the details when it comes to choosing the right piston ring. For one thing, it depends on details such as slot design and fixing groove depth and width. For another, the material plays an important role and affects installation tolerances in its turn. You can find out here what is important for piston ring selection.

Mechanical requirements for piston rings: pressure, speed and lubrication

The most important factor in the selection of pistons rings is the pressure (force per area) which acts on the rings in the application. But frequency and speed of movement also play a major role. The type of lubrication and the coefficient of friction should also be taken into account. But why are these values so important?

Piston rings that are exposed to high pressure should be made of the most resistant material possible. Self-lubricating fibre-reinforced plastics or steels have become established here, although they have the disadvantage of being heavier and require constant lubrication. But speed of movement also plays a role. Depending on the material used, If the product of speed and pressure is too great, the resulting frictional heat cannot be sufficiently dissipated without additional lubrication. (see also: the PV value).

The type of lubrication depends on application requirements and the technical characteristics of the piston rings in question. Piston rings made of plastic or plastic fabric are often self-lubricating. Solid lubricants such as PTFE or molybdenum sulphide (MoS2) minimize coefficients of friction and protect the piston rod or cylinder from wear.

Piston ring shape and dimensions

Piston rings are mounted in two ways. They are either fitted on shafts or rods or installed as guides in cylinders. This is why guide rings are slotted: to provide the necessary clamping force and flexibility. Piston rings also serve as a sealing function or are designed to let lubricating or hydraulic oil through, depending on the shape of the slot. There are also angled and straight slots or form-fitting variants with a Z or tooth profile. Piston rings made of plastic offer the advantage of less complex shaping, since plastics can be processed and machined relatively easily and cost-effectively.

Material variety for piston rings

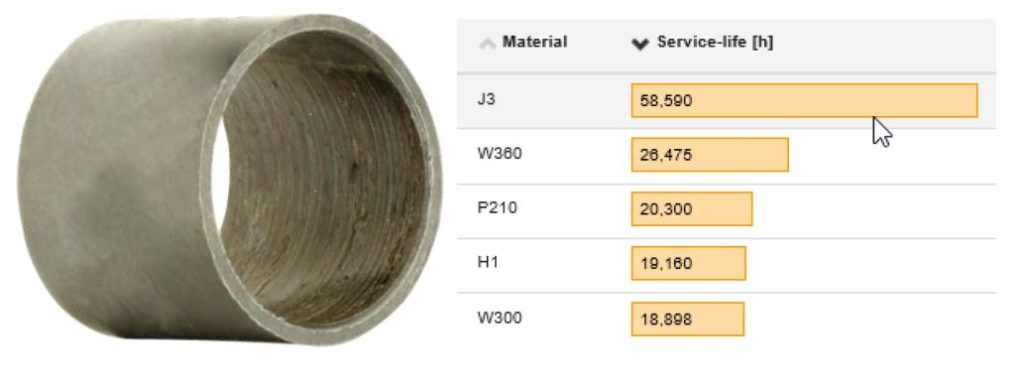

The world of plastics has an especially wide range of materials. Not all of them are suitable for piston rings. Additives are also required to specifically optimise the material properties for use in piston rings. In addition to such improved properties as elasticity, coefficients of friction, and mechanical stability, the materials differ primarily in their temperature resistance, thermal expansion, and chemical resistance.

The properties mentioned above and mechanical strength and elasticity, maximum PV values, and thermal properties can be compared especially well by means of data sheets. But what do they say about component durability and service life? Here the comparison is often difficult. Design programs and formulas can help here.

Are you looking for piston rings? We would be happy to assist you!

From requirement design to determination of the ideal shape, material, and finished component delivery, we will support you with our experts for plastics in bearing technology. Not just for high volumes, but also for prototypes and small series. Simply make a no-obligation appointment with our consultants or contact us directly. By phone, email, in person or virtually.