Connectivity in practice: i.Cee connection to a SIMATIC S7 machine controller from Siemens

Richard Habering | 25. March 2022

The smart plastics sensors from igus: they monitor abrasion, measure the pull/push force and provide information about an imminent overload. But how does the maintenance manager get concrete information about the condition of the system? The solution from igus for this is the i.Cee:local. The intelligent module bundles the data of all smart plastics systems used and prepares it for the maintenance engineer. Even if the i.Cee module impresses with its multi-connectivity, the direct communication path to the machine control is often the most important. That’s why today we want to take a look at the concrete web of connection using the example of a Siemens machine control system.

All modern plants or production machines are equipped with a PLC, i.e. a programmable logic controller (PLC), which is used for control system or regulation and is programmed on a digital basis. In the simplest case, the PLC has inputs, outputs, an operating system and an interface through which the user programme can be loaded. This user programme then determines how the outputs are switched depending on the inputs of the machine.

According to Wikipedia the connection of the PLC to the machine or equipment is established with sensors and actuators. In addition, there are status displays. The sensors are connected to the inputs of the PLC and communicate what is happening in the machine or equipment to the PLC. Examples of sensors are for e. g,. push-buttons, light barriers, incremental encoders, limit switches, or even temperature sensors, level sensors, etc. The actuators are connected to the outputs of the PLC and offer the possibility to control the machine or equipment. Of course, the smart plastics sensors can also be used here, which have the exact task of reporting the exact status of the energy supply system back to the user.

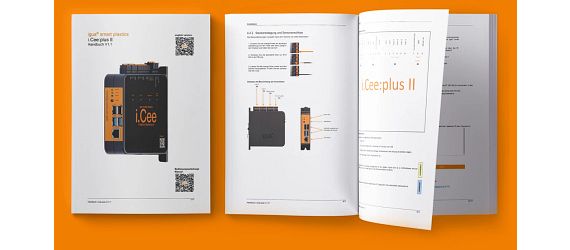

Using the widely used SIMATIC S7 control system as an example, we will briefly outline the next steps here. First, connect the PLC to the i.Cee:plus II module via TCP-IP using the RJ45 socket on the front panel. Further details on the numerous interfaces and connection diagrams of the i.Cee module can be found here in the new i.Cee manual. Subsequently, this sample programme of an S7, which contains a data block with the current input/output variables. This can then be loaded into the PLC via the associated Siemens TIA portal. Totally Integrated Automation (TIA) is the open system architecture from Siemens and ensures the seamless interaction of all automation components, the software involved and higher-level systems and services. This means that all smart plastics sensors can supply their recorded machine data directly to the PLC of the machines and be evaluated.

Sources:

- https://en.wikipedia.org/wiki/Programmable_logic_controller

- https://new.siemens.com/global/en/products/automation/topic-areas/tia.html