Can polymers be used at the high temperatures associated with bakery technology?

Bastian Mehr | 24. April 2020

Things can get hot when we move into bakery technology. This is a special challenge for bearings. It takes special bearings and bearing materials to handle the high ambient temperatures. Bearings are often used in applications where temperatures exceed 200°C.

There are a wide range of applications in ovens and their immediate vicinity in the bakery industry. Many bearings have trouble because the lubricants used quickly reach their limits.

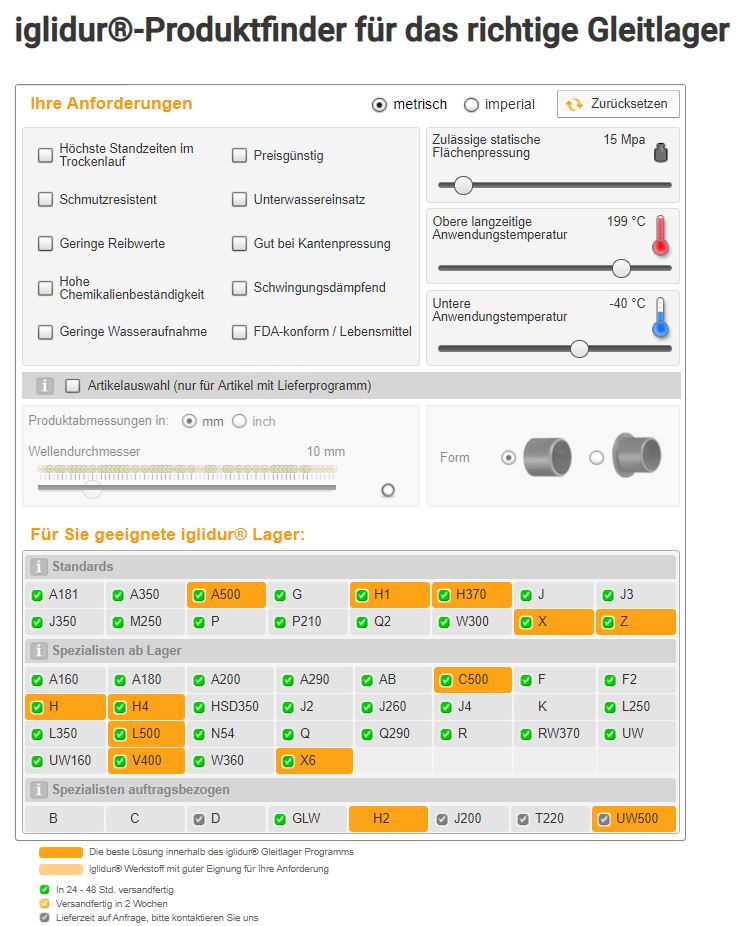

But what if the bearings you use don’t need any lubrication? This is where polymer bearings have a big advantage. For one thing, they are designed for dry operation and need no additional lubrication. For another, they can handle constant temperatures of up to 250°C. The selection of a suitable material is critical here. Polymers are not generally expected to be effective in moving applications in such high temperature ranges. But they do so, and well. At temperatures of up to 300°C for short periods. The key factor here is the application itself. It is important to know the application accurately and design it well. There are various materials that can be used here. It depends on the type of application. For hinges or levers, iglidur X can be a suitable material. In the area of material handling, such as transporting pretzels away from the oven, iglidur H1 is a good material for the guide rollers.

But if we get near open products, food-compatible materials become necessary. This is where iglidur A family materials come in.

https://www.igus.eu/info/plain-bearings-productfinder-iglidur-overview

Do you have any questions? We would be happy to support you in designing and selecting the appropriate product