Busbar system or energy chain?

Marco Thull | 18. March 2020

The performance of a crane is directly dependent on its electrification system. With various power supply options available and a range of application requirements to take into consideration, making a choice of which type of system to implement can be difficult. It is crucial to consider the advantages and disadvantages of prospective energy supply systems, whether for example busbar systems or energy chains, before deciding on an alternative.

Busbar system

One power system that is frequently offered for overhead cranes is an open or insulated busbar. These horizontal metal conductors are found to be a standard in many industries. They can be used in indoor or outdoor cranes, as well as on tracks with more than one bridge operating on them.

Most busbars are comprised of seven main components. The system supplies power along the track or bridge of a crane through steel or copper conductor bars. A collector arm slides along the conductor bar, allowing current to pass from the electrified conductor bar to the moving collector and on to the moving hoist or other travelling element.

Busbar systems are limited in the complexity and type of energy they can supply. On a busbar system, each conductor or pole requires its own conductor bar and collector.

Energy chains

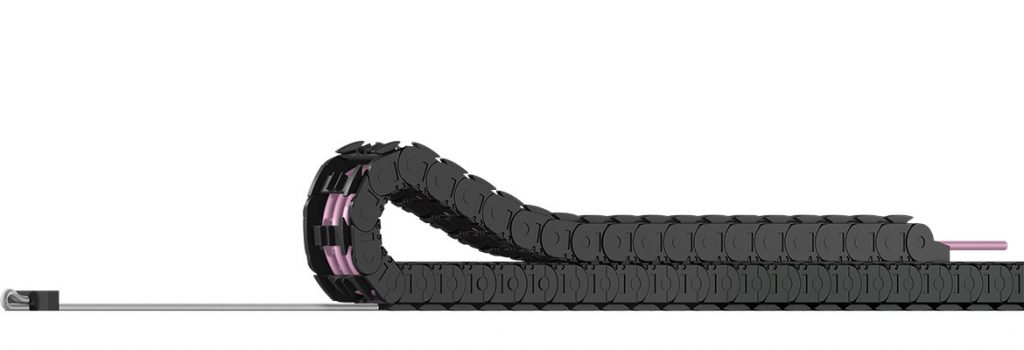

An electrification system that can solve the problems caused by busbars while providing superior performance for most applications, is an energy chain system. Often referred to as the lifeline of modern machinery, energy chains are high-strength plastic cable carriers that reliably protect cables during constant movement.

While busbars are comprised of many different components, energy chains are simply made up of parallel side links that are connected with crossbars along the top and bottom of the carrier. The design is modular and can be adapted to a wide range of applications. Specialised designs and materials are available for various types of motion and environmental factors.

More information

Learn more about this topic on our website or download the free white paper.

More on the topic of energy chains vs. festooning systems or motorised cable drums in the blog here

Also discover the new solution for storage and retrieval units autoglide 5, energy and data transmission installed in 1 hour.