Ball bearings or plain bearings in AGVs: That is the question.

Christian Strauch | 8. April 2020

Flawless transport systems are conquering more and more areas of industry – intralogistics in particular.

These small and large automatic guided vehicles, or AGVs, have one thing in common: they must function reliably 24 hour a day, seven days a week – ideally for a long period of time. Periodic maintenance is not desirable.

That means that the products installed must need virtually no maintenance.

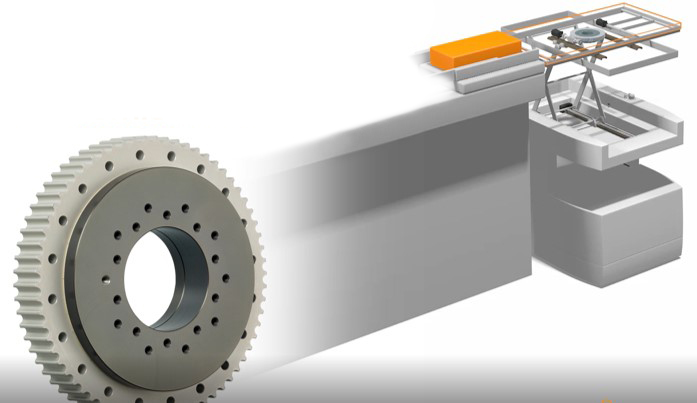

If you look at the inside of an AGV, you quickly see that the vehicle is packed with electronics. Each millimetre is used to full advantage. Of course the AGV also needs mechanical components, since it moves: it travels forwards and backwards and raises and lowers (and often turns) its platform. These mechanical components are largely installed on the bottom of the AGV, where maintenance personnel have difficulty reaching them. The first commandment is therefore “Thou shalt install low-maintenance or maintenance-free components.”

And this is where the advantages of igus maintenance-free bearings are most obvious:

It is fairly well known that igus bushings and linear bearings made of tribological polymer are used in AGVs. But what about slewing ring bearings? Why should slewing ring bearings be the plain bearings installed in AGV?

- Installation space: as mentioned above, the AGV’s interior is so packed that even the smallest screwdriver would not fit through. Each millimetre is valuable. Slewing ring bearings are welcome as plain bearings, since they require much less installation space than their rolling bearing counterparts. The diameter is variable, but the thickness and height of the slewing ring bearing is only 17mm, depending on the product!

- Maintenance-free: the liner, made of self-lubricating tribological polymers, makes the bearing maintenance-free!

- Static load: the surface pressures for plain bearing slewing ring bearings are substantially lower than for a ball bearing variant: in normal AGV operation, this is not a problem for the ball bearing. But in certain situations, such as emergency braking under load, ball bearings are point-loaded. This means that surface pressure is briefly very high and can destroy the bearing ring. The ball presses into the material. This cannot happen with a plain bearing. The force is distributed across a much greater area, which is why there is less surface pressure even under extreme conditions.

- Rotary movement: AGVs generally have no full rotary movement – they instead tend to swivel 135 degrees. “So what?” you might say. What difference does that make? If a ball bearing swivels in a certain range only, its lubricating grease is not completely distributed. The swivel movement can push the grease off into the periphery, so to speak. You quickly have a spot on the ball bearing that is not getting any lubrication. Dry operation ensues, followed by failure. Plain bearings do not have this problem, since solid lubricant is integrated into the polymer.

- The price: a nice side effect is that customer-specific igus slewing ring bearings can be offered at a much lower price (up to 40% lower) than their ball bearing counterparts.