Axial clearance

Zoe Moser | 5. November 2020

Axial clearance – what exactly is that?

How exactly is axial clearance defined? What must we watch out for? And what possibilities does igus offer for reducing axial clearance?

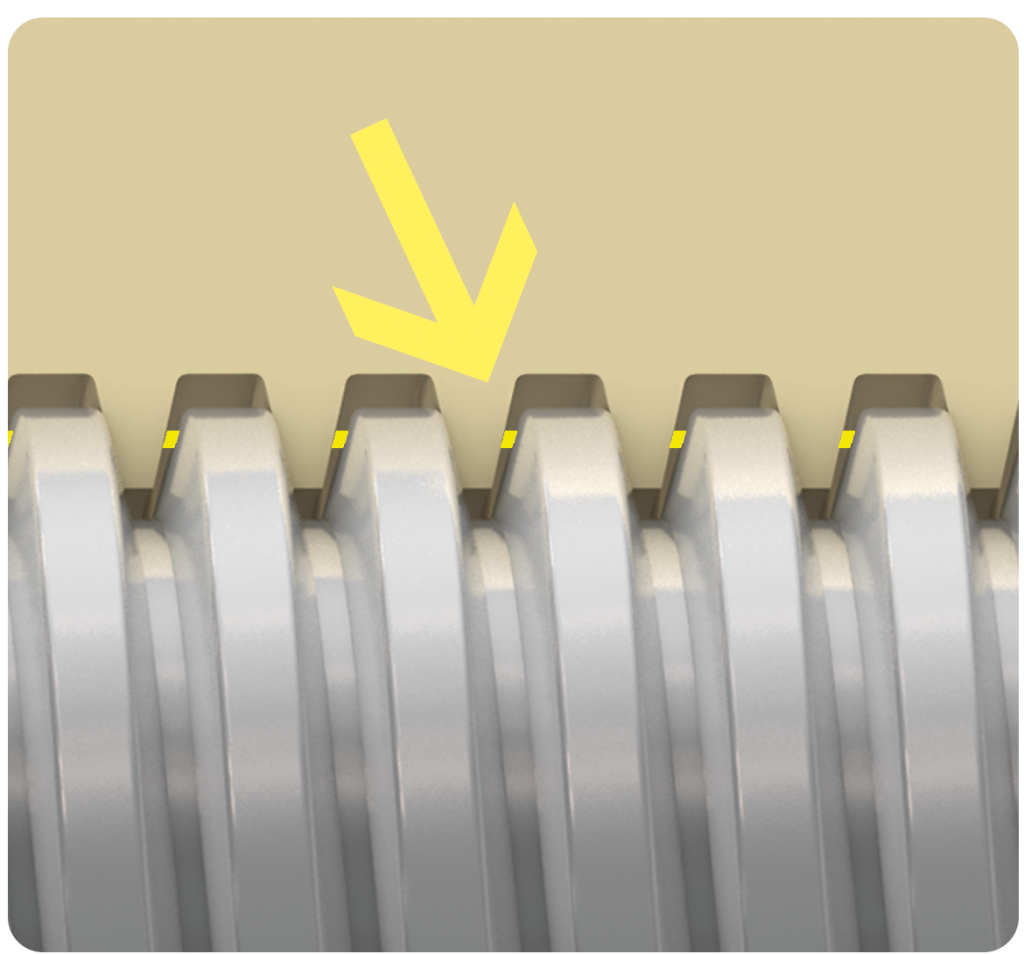

The question of clearance is often asked in the case of lead screw nuts made of polymer. This describes the lost motion, i.e. the “dead travel” on the lead screw, or in other words the gap between the thread flanks of the lead screw and the lead screw nut. The term clearance is often used in general. In this context the correct technical term is axial clearance. It describes the movement of the lead screw nut in axial direction without movement of the lead screw.

Lead screw units require a minimum clearance to maintain their function. If the axial clearance is too small, the torque required to move the lead screw nut will also increase.

What I need to consider

In addition to the axial clearance caused by the manufacturing tolerances, the application-specific influences must also be taken into account. In addition to thermal and hygroscopic environmental influences, the minimum clearance to be considered in the application must also take into account the friction heat generated by the application. This plays a decisive role in connection with the expansion behaviour of the polymer material used. As the axial clearance in the system can change with temperature fluctuations.

How can I reduce the axial clearance?

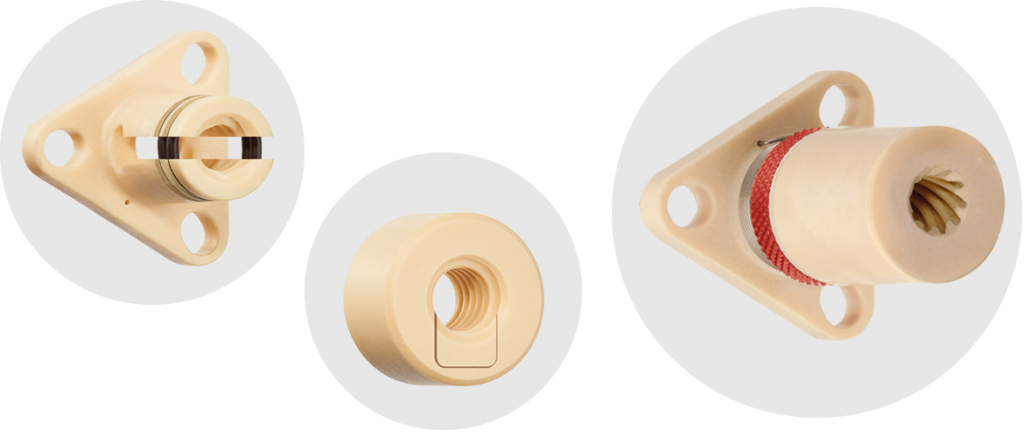

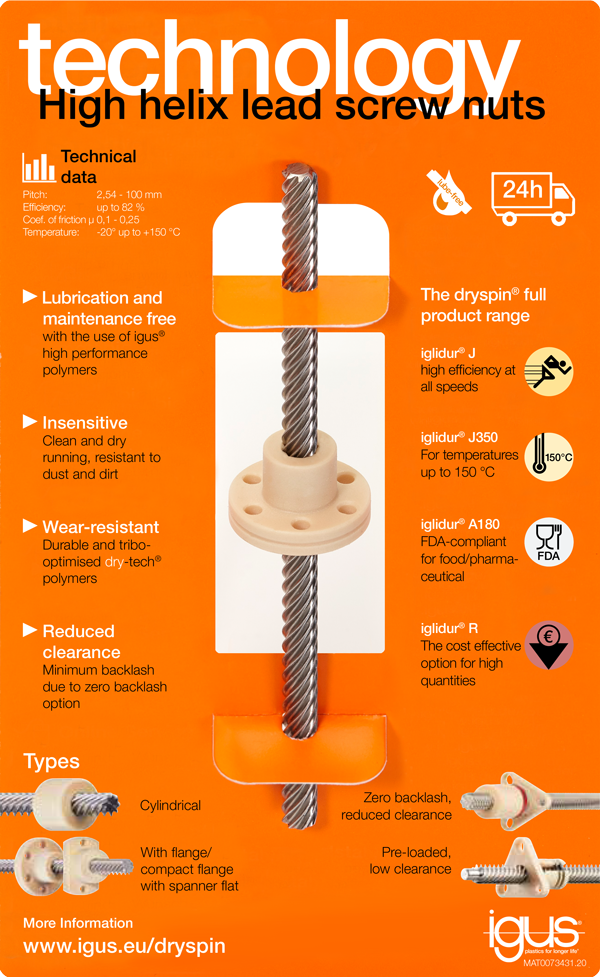

To reduce the unwanted clearance, in addition to the correct choice of material, a pretension mechanism has proven to be an effective measure. For our dryspin® high helix threads and trapezoidal threads there are three versions with pretension: Zero-Backlash, Low-Clearance and AB lead screw nut. Here you will find all the advantages and assembly instructions for our clearance-reduced lead screw nuts.

For applications with high loads, high temperatures or in heavily polluted environments, a standard lead screw nut should always be used. The reason for this is that all three principles are cancelled out by too high loads. For this reason, the maximum static axial loads are specified separately for each lead screw nut model.

Want to test lead screw technology?

Request a free sample of dryspin here.

All information at a glance!

Do you need more information?

Have a look at our home page!

All information about lead screw technology.