Automated plastic production? Yes, with igus Low Cost Automation

Christian Schäfer | 26. March 2020

The decisive factors in the plastic processing industry are efficiency and productivity. That is why automation processes such as machine feeding, component handling and pick-and-place processes are essential components of modern, economic production.

Low Cost Automation in industrial use

Automation made easy with igus Low Cost Automation. Cost-effective, easy-to-implement, individual solutions for more efficient plastic component manufacture. All products developed by igus for automation are used in many of our own production applications.

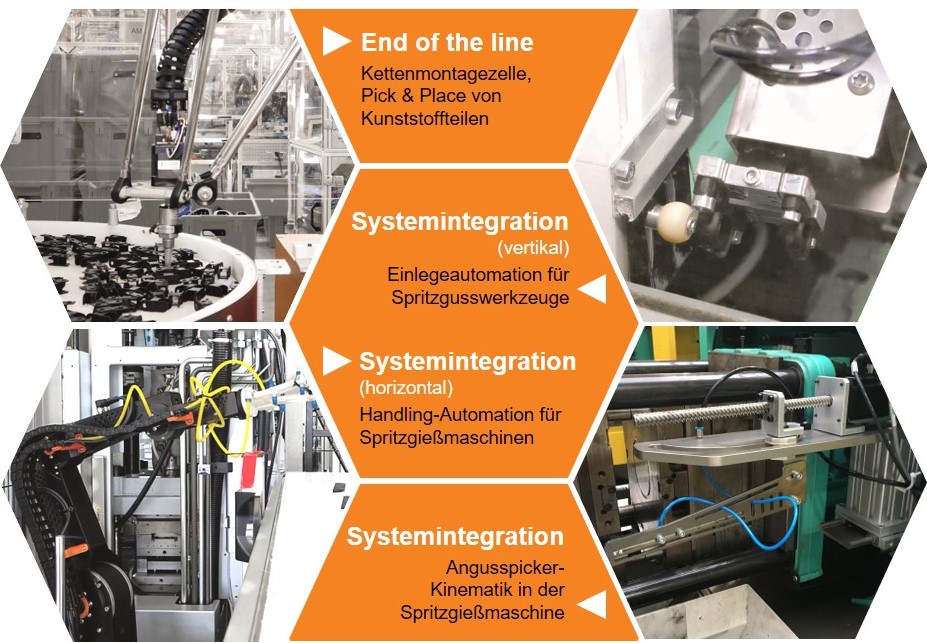

robolink and drylin multi-axis articulated linear robots with appropriate control systems and drylin delta robots as a pick & place unit, automated together and fully lubrication-free and maintenance-free e-chains in the igus factory in Cologne.

robolink multi-axis articulated robots support handling automation for injection moulding in such capacities as machine feeding for overmoulded components.

Fast, automated gripping of plastic parts in the injection moulding process can significantly improve the cycle time. The sprue picker developed at igus is already in use in more than 60 production machines and allows immediate separation of sprue from components in just 1.25 seconds.

How can igus products help you automate your plastics production? For injection moulding, extrusion, additive manufacturing or processing and subsequent steps, igus Low Cost Automation ensures a fast, economical introduction to industrial automation.