Additive manufacturing in special vehicle construction

igu-blog-adm | 9. April 2019

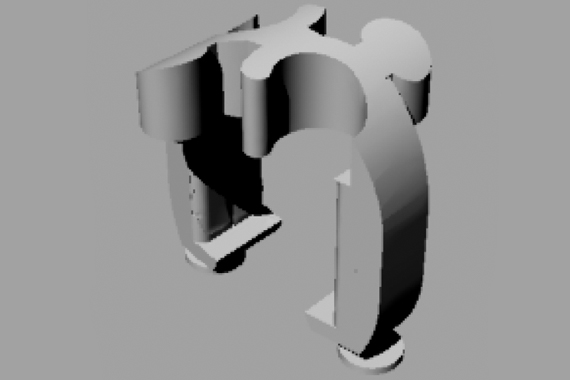

Motorists with disabilities benefit from “Darios”, a digital gas ring. This allows you to give throttle with your hands on the steering wheel. “Darios 211” consists of over 200 identical parts that slide over the flattened steel ring. These parts consist of iglidur® I3 and are manufactured in 3D printing.

How does the gas ring work?

The company KEMPF develops equipment in the field of special vehicle construction, to be more precise, for disabled drivers. Darios, the digital gas ring, allows a driver who cannot use his legs to accelerate with his hands on the steering wheel. The sleeve of the steel ring must rotate freely so that the driver can easily control the acceleration when leaving a curve; the steering wheel then slides back into straight position with his fingers.

What was the customer’s problem?

As long as the steering wheels were round, the case was a plastic part covered with leather. Now more and more steering wheels are flattened, so a solution had to be found to keep the sleeve turning freely over a flattened ring. A special component with the geometry of the glider by mechanical processing to manufacture was impossible.

source: www.kempf-gasring.de/

The Solution

This is how the DARIOS 211 was created. It consists of over 200 identical small parts that slide over a flattened steel ring. These parts are manufactured in

iglidur® I3 by the igus® 3D printing service. The most important advantage of iglidur® I3 is, that no lubrication is necessary. This is very important as the company KEMPF offers a 30 year warranty for all its equipment. The parts are covered with elastic leather. The ring looks elegant and the customers are enthusiastic.

3D printing: low-wear plastic components for the automotive industry - igus Blog

[…] That way, noise-sensitive applications inside motor vehicles, such as sliding elements at the steering wheel, are realised with readily available and cost-efficient printed special parts by igus. The goal is […]