Abrasion behaviour of cables

Stefan Wehrmann | 5. November 2020

Abrasion behaviour or abrasion resistance are terms which are often used in connection with cables in e-chains. Because the abrasion behaviour is essential for the durability of a cable.

Why do cables have to be abrasion-resistant?

To make a long story short: so that they last longer. The longer, the better. Depending on the application, cables are more or less stressed. If the abrasion behaviour of a cable is poorly adapted to the respective application, this can lead to defects and ultimately to machine failures.

Where are abrasion-resistant cables used?

Basically the specification of abrasion resistance is useful almost everywhere. However, abrasion-resistant cables are of great advantage, especially in continuously moving applications. A prime example of this is the use in energy chains.

Short, fast and constantly repeating cycles (so-called double strokes) and small bend radii present the components with several challenges. Here a strong friction between the cables and the individual chain links or separators can occur. Extreme examples are pick and place machines and pick & place applications.

Consequences of incorrect cable selection

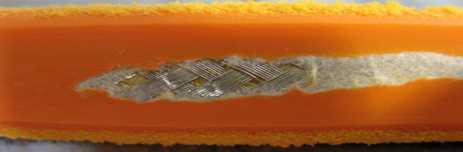

Non-optimised outer jacket materials quickly reach their limits here. The following picture shows clear consequences of the wrong cable selection. The outer jacket is rubbed off here down to the shield. If this is the case, the electrical safety and the function of the application are significantly endangered.

The problem also occurs on long travels, such as with cranes or stacker-reclaimers. As with very dynamic applications, special materials are required for the outer jacket to counteract rapid wear and expensive downtime. The material TPE has proven to be particularly suitable in countless tests in the laboratory and in the field.

Which cables are highly abrasion-resistant?

In principle, cables for highly dynamic applications should always have a very high abrasion resistance. However, often only supposedly suitable models are used for these applications. Apparently sensible solutions, such as heavy rubber hose cables, often prove to be an expensive bad investment, as they are only slightly suitable for use with energy chains.

It is better to delve deeper into the subject matter here and make the selection, if necessary together with an expert in the field. Cables from igus are all highly abrasion-resistant and therefore offer numerous application possibilities.

Do you distinguish between different levels of abrasion resistance?

Yes. This is especially true for the outer jacket materials used. TPE, PUR, PVC.

When it comes to abrasion resistance, for example, PVC shows significantly better behaviour than PUR. TPE can be described as the most abrasion-resistant material.

However, this cannot be generalised. Materials from different manufacturers can only be compared to a limited extent and are developed for different purposes. Compounds not optimised for the energy chain can lead to much worse results.

We encounter similar situations in everyday life: nobody would ever think that exactly the same material is used for PVC pipes and artificial leather jackets. In this case too, different PVC compounds are used for different purposes.

Conclusion

The necessary abrasion behaviour of a cable is always related to the application. Depending on the intended use, the cables must be more or less abrasion-resistant. Although there are fundamental differences in the quality of the individual jacket materials, the expensive ones are not always better. You can make some statements with the help of our product finder. But we would also be happy to help you personally and in detail.