How can chain-compatible cables extend service intervals?

Beke Nieszytka | 1. October 2019

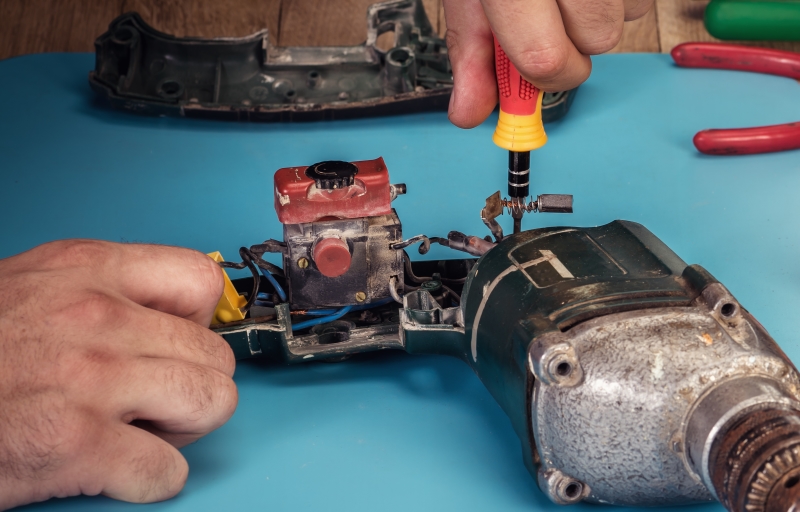

At some point, you have certainly had to deal with a loose contact. It may have been at home when you were ironing clothes or using your drill.

Fun fact:

A loose contact is a point that causes the transfer resistance within the circuit to fluctuate greatly or causes unintentional circuit interruption from time to time. A loose contact can be due to loose plug-in connectors or manufacturing defects (such as cold solder joints).

If the defective electrical connection occurs in an industrial process, a negative spiral can develop very quickly. The focus is on reducing machine downtime due to servicing, set-up or failure and on increasing production output. If a fault occurs in a production chain and planned production steps cannot be completed, productivity is affected in a very short time.

Cables – flexible or suitable for drag chains?

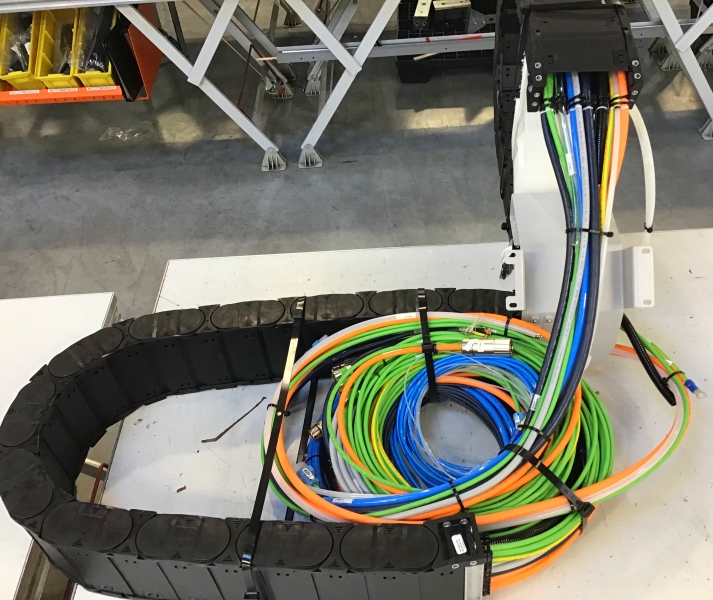

Modern machines often have flexible cables in accordance with a relevant DIN standard, such as DIN VDE0298-4, DIN VDE0207, DIN VDE0281-1 or DIN VDE0281-2. However, the various standards say nothing about the purpose of use in an energy chain. Manufacturing rate increases, accelerated travel speed, and constricted installation spaces quickly challenge these cables to their limits, and they are unable to meet requirements. In these cases, special cables that have been designed to meet demanding bending, torsion, abrasion, chemical resistance, or welding spark requirements, offer a solution.

Many of these cables, such as torsion-resistant cables for robots, chain-compatible cables for linear movements, or cables for hanging applications where the cable’s dead weight influences its structure are particularly suitable for special applications. Here, no distinction is made between shielded and unshielded control, power, or bus cables.

Fibre optic cables (FOC), can also be adapted to the purpose for which they are being used. Special cable design enables you to avoid typical faults such as cable breakage, corkscrews, wire breakage, EMC problems (shield wire breakages), and jacket abrasion, extending your service intervals.

“Special cables? That sounds complicated and expensive and certainly means a long delivery time.”

Wrong on all three counts.

| … complicated? | … expensive? | … long delivery time? |

| No, igus® offers sophisticated online configurators that make choosing easy. | No, igus® cables are produced in a highlyautomated process and offer considerable price advantages, even in small batch sizes. | No, igus® has more than 6,000 plug-in components in stock, and its streamlined processes allow speedy delivery at no extra cost. |

| The readycable® product finder helps you to choose the right cable |

igus® helps you make the right choice for your application

For the reasons stated, igus® has in the past focused on creating a specially optimised range of cables, acquiring extensive expertise over the years. All the cables are documented in detail on the igus® data sheets, which provide a great deal of useful information to help make the right choice for your application.

All cables are tested in the company’s own 3,800 m² test laboratory, igus® gives all its customers a chainflex® guarantee of 36 months or 10 million double strokes.

In addition to cables sold by the metre, igus® offers a harnessing service for a wide range of readycable® cables, using plug-in connectors from market leaders to make the cables completely compatible with the components installed in and on machines. All ready-to-connect cables have been thoroughly tested and can be ordered in the desired length (to the centimetre), with no minimum order quantity.

Visit our readycable® product finder and find the right cable for your application.