Technical plastics vs. high-performance plastics vs. plastics for movement

Marco Thull | 5. June 2023

Technical plastics

Technical plastics are a subgroup of thermoplastics that differs from standard plastics, high-performance plastics, and functional plastics in terms of properties and price (1). They are used for many applications including bearings, rollers, wheels, seals, and moulded parts (2).

Examples of technical plastics include polyvinyl chloride (PVC), polyamide (PA), polyoxymethylene (POM), polycarbonate (PC), and polyetheretherketone (PEEK) (3) (2) (4). These materials have specific electrical, thermal, and mechanical properties that make them suitable for specific applications (5). Technical plastics are usually produced in injection moulding, extrusion or other special manufacturing processes (6).

Sources:

1) https://en.wikipedia.org/wiki/Engineering_plastic

2) https://tecoplast.de/technische-kunststoffe

3) https://www.fritsche.eu.com/produkte/kunststoff/technische-kunststoffe/

4) https://kdfeddersen.com/competencies/engineering-plastics/polymers/

5) https://www.buckundsohn.de/fertigteile/bearbeitung-technischer-kunststoffe/

6) https://www.ggbearings.com/en/why-choose-ggb/faq/bearings-faq/what-ep-or-engineered-plastics

High-performance plastics

High-performance plastics, also known as high-tech plastics or high-performance polymers, are a subgroup of plastics that meet higher requirements than standard or technical plastics. They are more expensive and used in smaller amounts. High-performance plastics differ from standard plastics and technical plastics primarily in their temperature stability, chemical resistance, and mechanical properties. They are used where standard plastics or technical plastics cannot meet the requirements. High-performance plastics are an alternative to metal or ceramics and offer a number of advantages. In many cases, they can replace metals or ceramics. Examples of high-performance plastics include liquid crystal polymers (LCP), polyethersulfone (PES), and polyphenylene sulphide (PPS). In the category of high-performance plastics, one or more properties are greatly improved, depending on the application (7) (8) (9) (10).

Sources:

7) https://www.tw-plastics.de/en/products/high-performance-plastics/

8) https://www.terplastics.com/en/products/technical-plastics/high-performance-plastics.php

9) https://en.wikipedia.org/wiki/High-performance_plastics

10) https://tecoplast.eu/high-performance-plastics

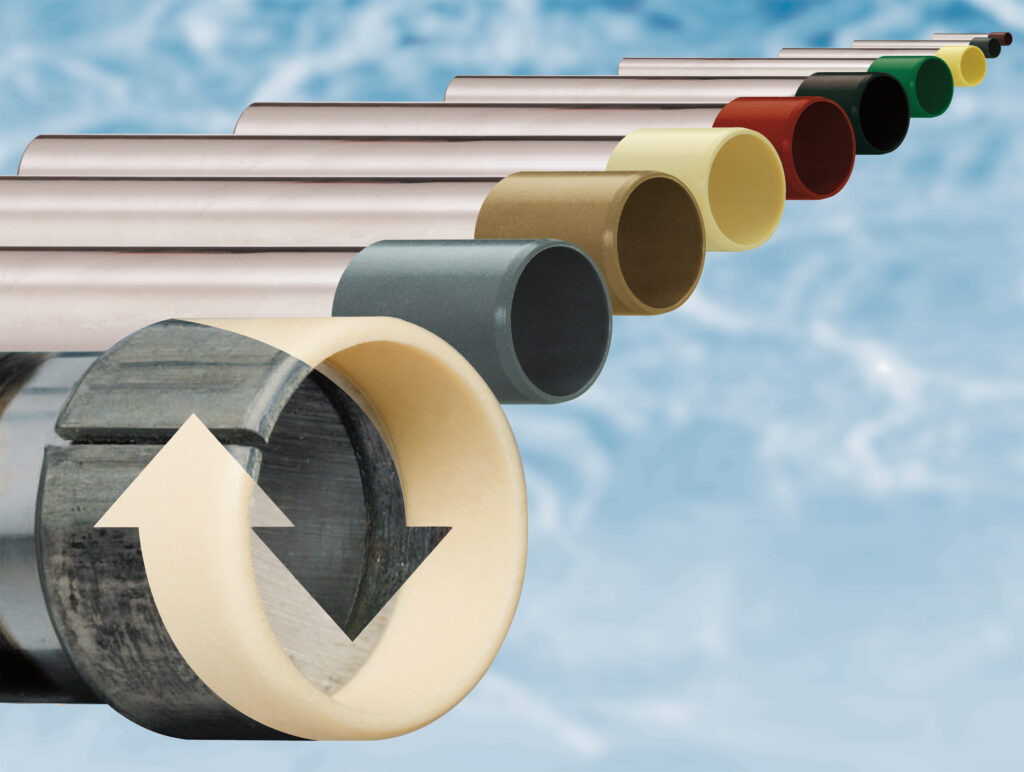

Picture igus GmbH: igus igubal plastic spherical balls, or motion plastics

motion plastics

motion plastics, or tribo-polymers, are a type of high-performance plastics optimised for friction and wear. They are used where standard plastics or technical plastics cannot meet requirements. motion plastics are designed to reduce costs and extend service life. They have enormous potential in industry and offer a multitude of advantages. The technology consists of tribo-polymers, or high-performance plastics that have been optimised for friction and wear. These materials are used in moving applications such as plain bearings, linear guides, and vertical farming automation. motion plastics are lubrication-free, often FDA-compliant, and resistant to dirt, dust, and soil. They are also corrosion-free and low-maintenance. igus is a manufacturer of motion plastics and develops and tests tribologically optimised high-performance plastics for moving applications (11) (12) (13) (14) (15).

Sources:

11) https://www.igus.eu/info/products

12) https://jisigus.com/brochures/EU_industry-solutions_web.pdf

13) https://insights.globalspec.com/article/19186/ecological-plain-bearings-made-from-regranulated-tribo-plastics

14) https://www.igus.eu/info/linear-guides-dry-tech-tribopolymer

15) https://www.foodmanufacturing.com/products/food/product/21114597/igus-how-motion-plastics-make-vertical-agriculture-sustainable