SHHH! It's nice to be quiet sometimes!

Patrick Czaja | 29. April 2022

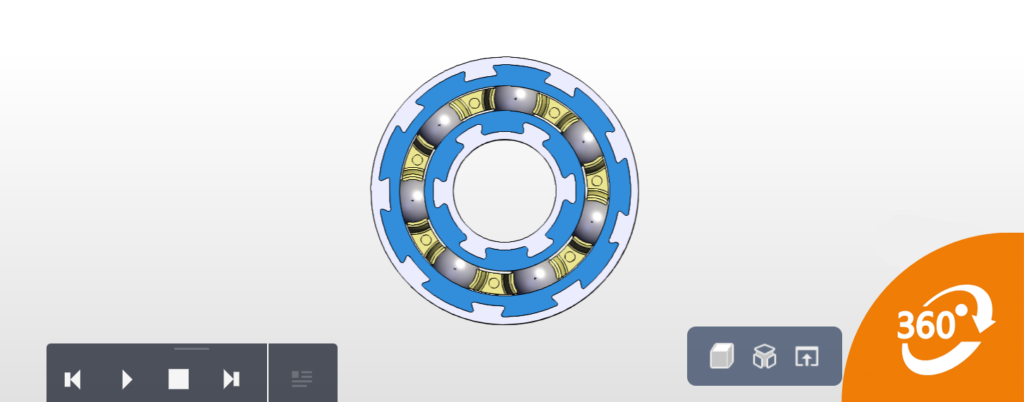

Have you ever seen a plastic ball bearing with races made of two different materials? This two-component ball bearing is intended for applications where high speeds and low noise are required. But what is the advantage? The blue xirodur D180 material is very wear-resistant and responsible for the low noise characteristics. Since the material is very soft, a single-component variant could fall apart. So the soft material is cast into a hard shell – a world first that won the 2022 iF Design Award for exceptional product design.

Following the principle that “You can cover more requirements with two components than with one,” the xiros team has embarked on a long path of development. The result is a ball bearing for industrial applications consisting of two components. Because the soft xirodur D180 is cast into the hard shell of both races, the balls always run on the soft high-performance plastic during rotary movement – supported by the hard outer shell. The ball bearing races with undercuts also ensure a high level of safety when the materials are connected and reliably prevent the running layer from detaching during rotary movement. Ball spacing is maintained with a wear-resistant cage made of iglidur J3. This material features special wear resistance, low coefficients of friction, and media resistance.

- Dimensionally stable and vibration-damping

- Suitable for high speeds

- Silent

- Long service life thanks to the combination of two polymers, and thus lower maintenance costs

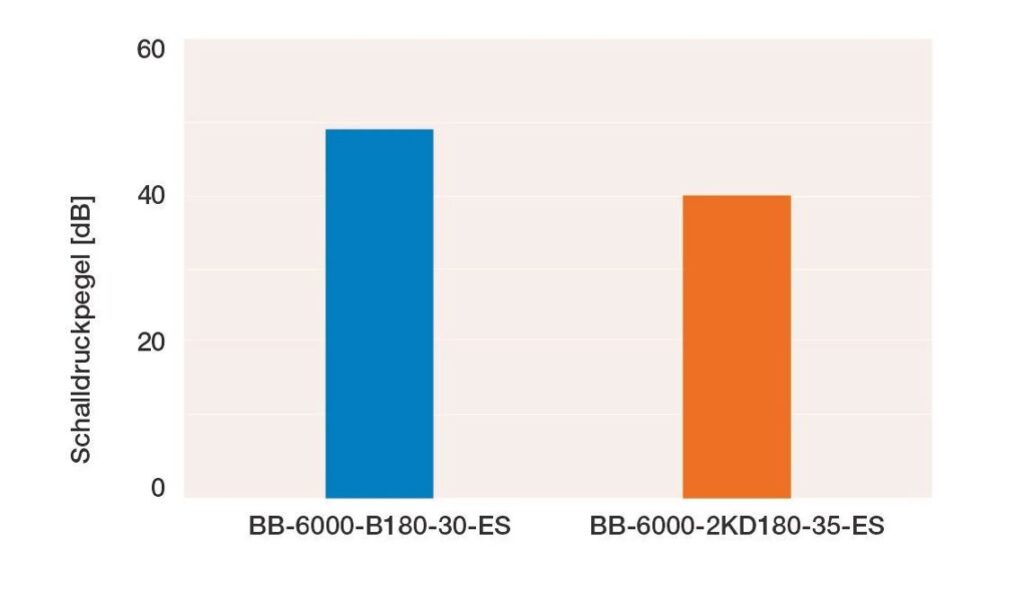

Noise measurement in the igus test laboratory: About 9dB quieter than standard ball bearings made of xirodur B180

Imagine a bowling ball rolling hard across the parquet floor – do you “hear” the rolling noises, amplified by the soundboard of the parquet? That’s exactly what happens with a “hard race.” Structure-borne sound increases the volume even more, and it gets worse when such a ball bearing is installed in a resonating body. The soft running layer dampens the noise and prevents the transmission of structure-borne sound. The result is a very smooth-operating whisper ball bearing which in this case is also particularly wear-resistant.