Seat height adjustment – permanently quiet thanks to innovative plain bearing designs

Sebastian Bloechl | 12. May 2021

Seat height adjustment in the car is an important component for comfort and safety, yet it is often given little attention by the vehicle owner. One main reason for this is the rather small number of adjustments. As a rule, the seat height is set once when the car is purchased and left in the same position for years.

Why is this changing now?

The development of autonomous vehicles, as well as the demand for car sharing services, is picking up noticeably. This also increases the number of different drivers of the same car. And this is precisely where the seat height adjustment plays a decisive role. The right seat height provides the best view of the road and is an important contribution to the feeling of comfort and safety. This is also a reason for the increasingly common use of electric seat adjustments by means of actuators and compact motors. All these reasons result in an increasingly frequently used seat height adjustment.

Higher loads and requirements on the plain bearings within the seat height adjustment system

Even for a small number of seat adjustments, a high quality bearing is needed, but the increased use of seat height adjustment brings a greater challenge to the plain bearings used. These now have to withstand significantly more movements and loads than before. Economical counter partners (e.g. rivets) and a low fine-cut portion ensure enormous load and wear requirements. Thin gliding layers on metal bearings can quickly become damaged or worn. The resulting noise is extremely undesirable because the seats must remain quiet and adjustable without squeaking (BSR) for the entire life of the vehicle. Accordingly, the plain bearing material used in the seat height adjustment is responsible not only for minimising wear and friction, but also for mitigating BSR and NVH noise within the seat structure.

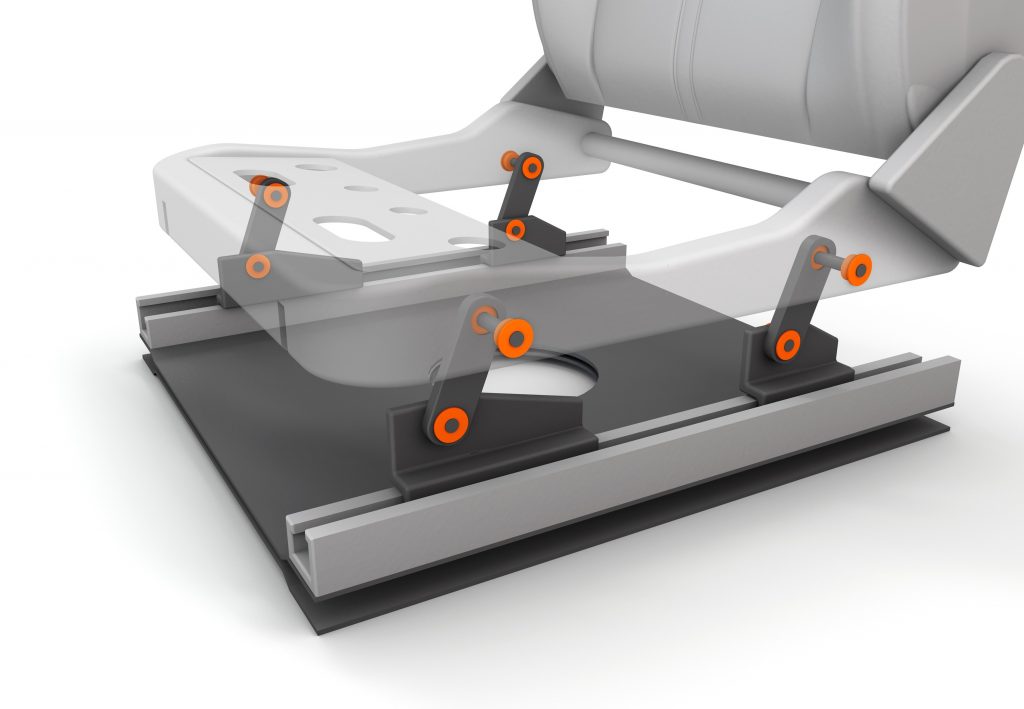

Where are the bearing points in the seat height adjustment?

The bearing points of the seat height adjustment are located between punched sheet metal hinges and sheet metal bindings or metal structures. Due to high and increasing demands on weight and loads, seat manufacturers are testing and ensuring the service life of the plain bearings. Otherwise, a car seat that is difficult to adjust or squeaks will reduce the quality for the user.

Innovative plain bearing designs for seat height adjustment – saving time and money

Many millions of seats are equipped with various bearing points within seat height adjustment every year. Therefore, the assembly times of the plain bearings used are particularly crucial – every second saved and reduced workstep brings great productivity benefits.

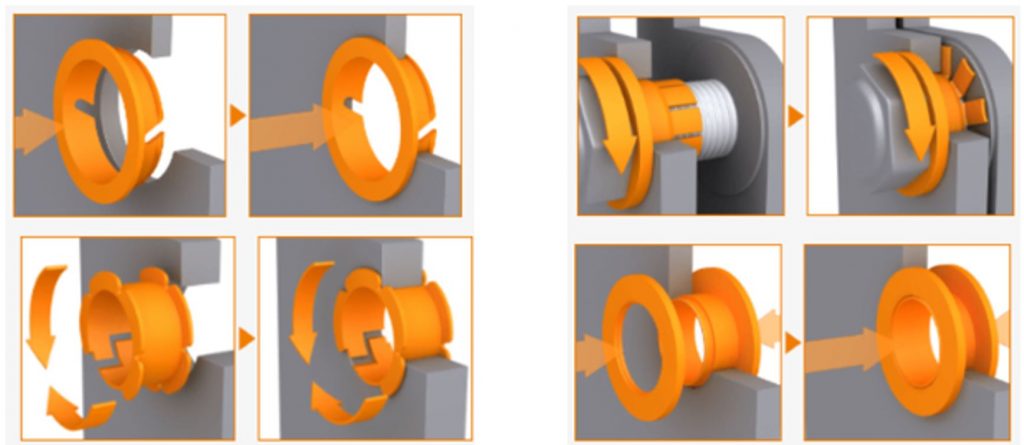

The innovative assembly concepts of igus plain bearings are particularly popular for hinge connections in, amongst other things the seat height adjustment. The igus clip bearings are easy to handle and increase efficiency. The flange processes and recalibration steps common to metallic plain bearings are eliminated. Further advantages are the weight (up to 5x lighter) and parts price reduction (up to 40%) compared to the metal version.

We would be pleased to present further advantages and possible applications of our tribologically optimised polymer plain bearings.

Do not hesitate to call me:

Sebastian Bloechl

Phone: +49(0)2203-9649-7718

Mobile: +49(0)173-4537974

Online: Linked.in

e-mail: sbloechl@igus.net

Free online consultation: igus Chat, MS Teams, Skype, Whatsapp, WeChat

Follow us on: LinkedIn, Instagram, Facebook

Have fun browsing and thanks for your time.

PS: from plain bearings to spherical bearings to linear bearings to ball bearings to special sliders to gears to individually customised design, the iglidur Designer leaves nothing to be desired. Request your part now and receive a quote by tonight.

More information: automotive industry, polymer plain bearings for automotive interior, exterior and engine compartment applications

Dinesh

Sheet height adjustment karna hai