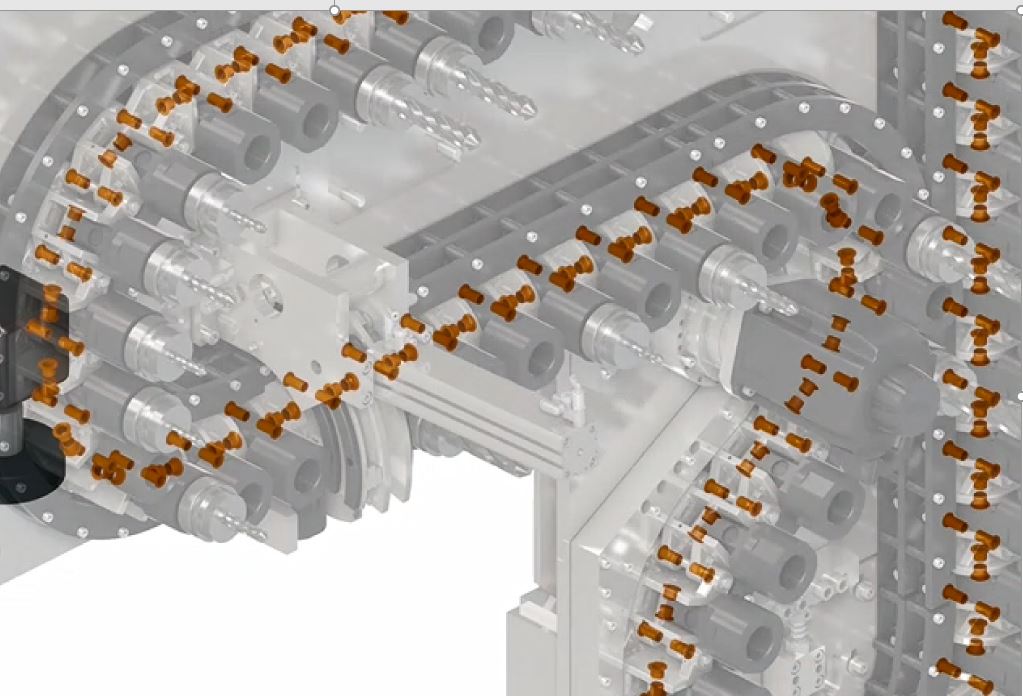

How to improve the chain magazine with plain bearings?

Volker Beissel | 24. March 2021

Wherever precision in the µ range is required in the machine tool, plain bearings made of plastic reach their limits. However, in places where this is not the case, they can reduce costs and minimise maintenance. A typical place where our plain bearings show their full strength is in chain magazines of tool changing systems.

The main task of the chain magazine is to hold a large selection of tools and make them available to the spindle when required. This means that this application stands still for the majority of the machine’s life. At the same time, however, the chain must be permanently operational, i.e. it must be mounted with as little friction as possible between the chain links. This relatively small movement in the joints also results in poor lubricant distribution in the bearing points. This in turn is often compensated with more lubricant.

This is exactly where our polymer plain bearings offer a good alternative. Due to the solid lubricants in the polymer bearing, there is no need to grease the chain. All framework conditions of the application can also be calculated, which makes the application maintenance-free and fail-safe.

At this point, it is important to choose the right material, because the bearings come into contact with coolant residues. We can resort to many different materials here to ensure that even the most aggressive coolant has no effect on the bearing point.

The vibration-dampening specifications of the polymers offer a further advantage. In machine tools in particular, the aim is to keep everything as low vibration as possible in order to eliminate negative influences on the milling surface.

And last but not least, it is always about reducing costs. Either by replacing the previous bearing solution or by dispensing with hardened bushings and pins for plain bearings.

Conclusion

Polymer plain bearings are the better solution in the joints of the chain magazine. They eliminate the need for lubrication, are resistant to coolants, reduce vibrations and can replace expensive materials.

Additional links:

Application example: https://www.igus.eu/info/plain-bearings-machine-tools-manufacturing?L=en

Further information on plain bearings: https://blog.igus.eu/die-3-groessten-irrtuemer-ueber-kunststoff-gleitlager/