Condition monitoring and predictive maintenance in clean combination

Richard Habering | 19. March 2021

What is it?

Condition monitoring and predictive maintenance optimally belong together and complement each other in a good system. The clean combination comes quite simply because we are talking about a train wash facility here. I would like to say that everyone knows a car wash. Some of you may have already noticed the energy chain on the side, below the ceiling. Car washes/car washing lines have a length of 60m or maybe even 100m. However, a train washing facility is up to 200m long. To cover this total length and different train lengths, the 200m are divided into 66m long segments with washer wagons. To ensure that this orchestra of washer wagons always works perfectly, all travel paths are equipped with condition monitoring systems (EC.P = push/pull force monitoring). Predictive maintenance takes over the function of the conductor. The latter knows at any time exactly what is being played and how long the symphony will last.

Why was the whole thing done in the first place?

Everyone loves that moment when the train pulls into the station on time and the journey finally starts. This perfect moment must not be marred by a dirty train. For this reason, Luxembourg Railways has opted for condition monitoring in conjunction with the predictive maintenance concept. This is because, unfortunately, in the past, there have been more and more “disruptions in the operational process” at the wash facility. These malfunctions were partly due to faults in the energy supply system. The special feature of this train washing facility is its autonomous operation. In the event of a malfunction, rescue usually comes too late or, due to the massive damage, the repair simply takes a very long time.

What do the systems offer?

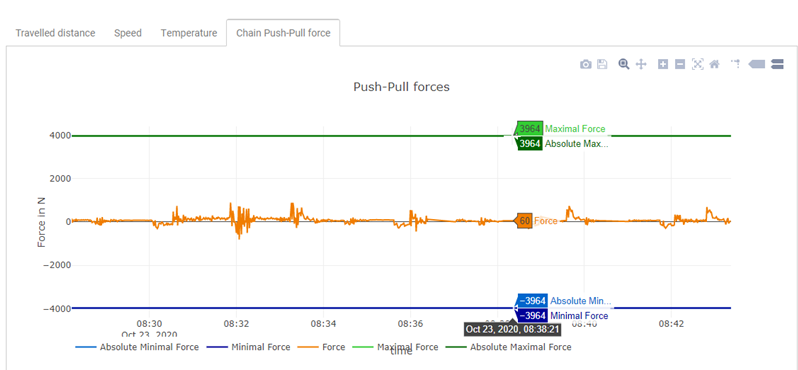

On the one hand, the wash wagons are equipped with sensors for condition monitoring, which stop the energy chain in the event of damage. Without these sensors, the wash wagons are driven until the e-chain or cables are totally damaged. This is because a rising e-chain falling out of the guide trough did not stop the wash wagons from continuing their journey. This danger is completely eliminated with the push/pull force measurement on each e-chain. The following picture shows the push/pull forces of a wagon in this train washing facility and its predefined force limits.

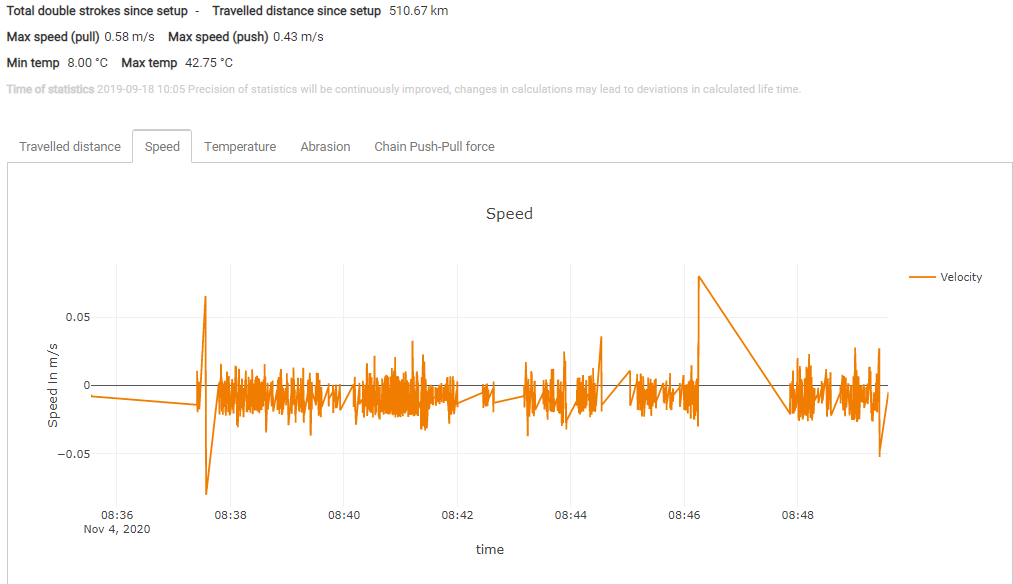

With condition monitoring, the system is protected against total loss. For a clean combination, the information on the service life of the energy supply system is still missing. After all, it is much better to know when damage will occur than to prevent a total loss. This is exactly the dream that predictive maintenance (i.Cee) fulfils. This technology looks into the future, adapts the service life forecast to the operating period and provides maintenance and inspection instructions. In addition to the data from condition monitoring, predictive maintenance also includes, for example, temperature, travel speed and distance travelled and is available to the user in various dashboards.

So that you don’t lose the overview, the i.Cee system also offers everything important in a dashboard. Everything at a glance.