How can a CNC machine be automated cost-effectively?

Volker Beissel | 15. March 2021

With regard to new machine tools, the digitisation of production is currently a topic of considerable interest. Everything is to become ‘smart’ and the milling machine itself should be responsible for re-ordering blanks. Large production facilities are already moving in this direction. But this solution is often still too expensive or unprofitable, especially for smaller production companies. If this applies to you as well, we will be happy to help you develop and implement your cost-effective solution yourself. In this regard, ensuring that you achieve a fast ROI (Return On Investment) is always an important consideration for us.

Where are the limits?

Our automation products are primarily suitable for small machines and workpieces up to 3 kg. Moreover, igus is not a system integrator but tries to provide you with everything you need in order to automate your machine on your own with a little technical skill. If you like working with lubricants, I have to disappoint you as all our products are lubrication-free and therefore maintenance-free as well.

What is the first step in automation?

The door is usually the place to start. In the first step, it is helpful if the machine door closes automatically after clamping and opens automatically after machining. You can then look through the open door to see where you can do what needs to be done. For this first step, you need a linear axis with drive and a simple control module. You can find the appropriate linear guides in our drylin E modular system, for example. Of course, our product range also includes the motor control you need, namely the D1 control system. We also provide our software for this free of charge. If the design is right, you can automate your machine door for less than €1,000. This saves you time during loading and unloading and reduces the downtime of your CNC machine. As stated above, we cannot connect it for you but we will be happy to help with the mechanical design of our components.

Is there also a cost-effective solution for the automation of loading and unloading?

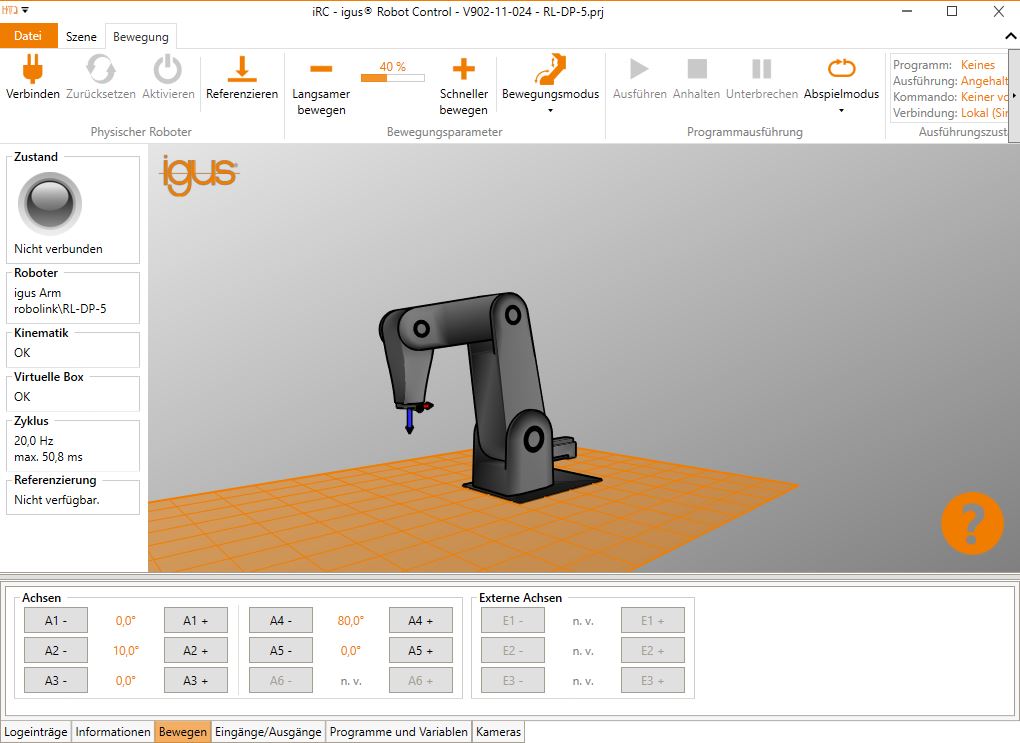

Once the doors open and close automatically, automated loading and unloading is the next goal. For this, you can place an expensive industrial robot in front of the machine or you can see whether our robolink is sufficient for your application. The great advantage is the very simple programming interface, which we also provide free of charge. From my own experience, I know that it takes less than 2 hours to program the movements of the robolink. The easiest way to put together your robot solution is to use the help provided by the website www.RBTX.com. There, you can put together all the products you need, from the robot to the gripper.

Conclusion

With our products, you can automate your CNC machine for less than €10,000. You can download and try out the complete software in advance free of charge. You can start to automate your machine with a fast ROI and perhaps have some fun as well.

Here, a compact summary of all the links again:

Drive technology overview: https://www.igus.eu/info/linear-actuators

drylin E linear guide: https://www.igus.eu/info/drive-technology-motors-overview

D1 motor control: https://www.igus.eu/product/17827

Robolink: https://www.igus.eu/info/robolink-robot-arm?L=en

Robot control: https://www.igus.eu/info/robot-control-system

Low Cost Automation configurator: https://rbtx.com/en