Lead screw technology product range

Zoe Moser | 2. October 2020

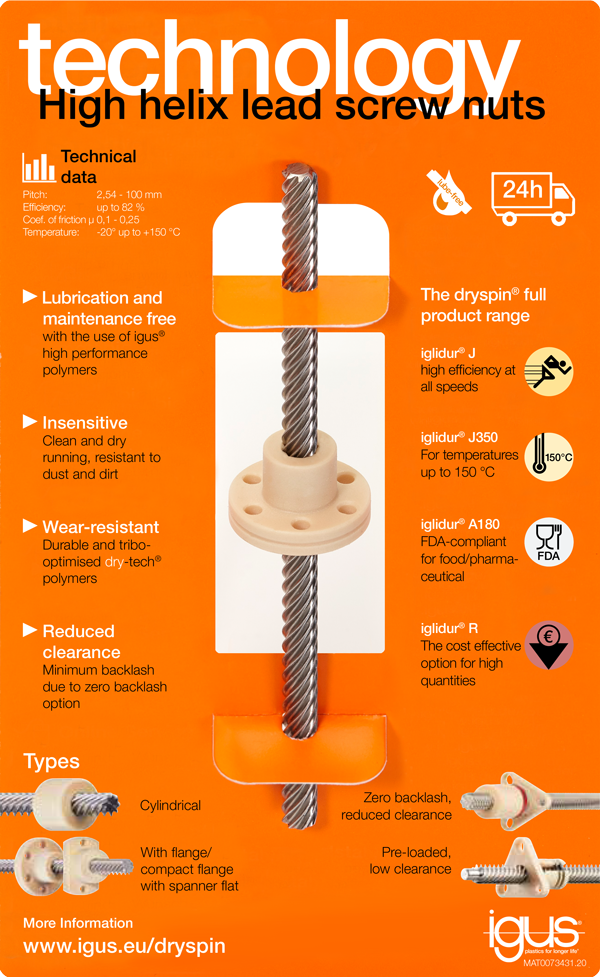

The dryspin lead screw technology product range

What does the dryspin product range offer? Which lead screw nut materials and lead screw models are available? And what are the specifications of these lead screw drives?

Let us now take a closer look at the dryspin lead screw technology product range. It offers a wide range of different lead screw nuts and lead screw models in various dimensions. The range includes diameters from 4 to 20mm and pitches from 2.4 to 100mm. Due to the diversity of the product range, the dryspin thread geometry is conceivable in almost all applications.

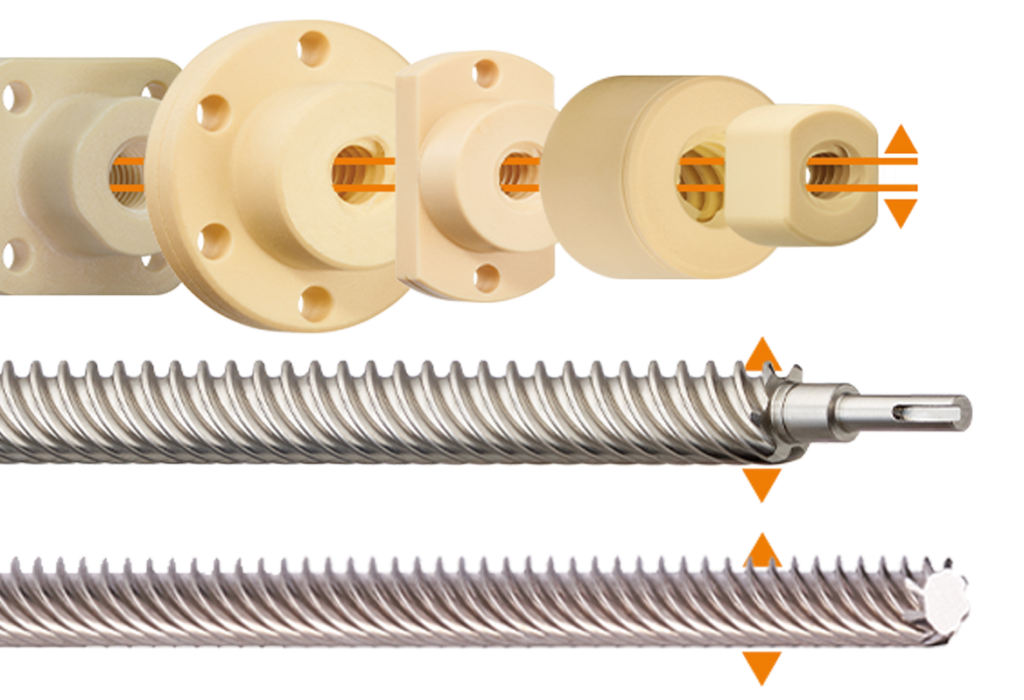

► Lead screw nuts in 6 different types

► In 6 different materials with individual specifications

► Lead screws in steep, trapezoidal and metric threads

► Available in stainless steel, steel or aluminium

Lead screw product range

The standard material of dryspin lead screws is stainless steel 1.4301, AISI 304. Thereby it is 100% corrosion-free and low wear. The lead screws are also available in aluminium.

Thread directions

All dryspin lead screws are available in the standard right-hand and left-hand thread directions. But also reverse lead screws for more design freedom can be easily configured and ordered from us.

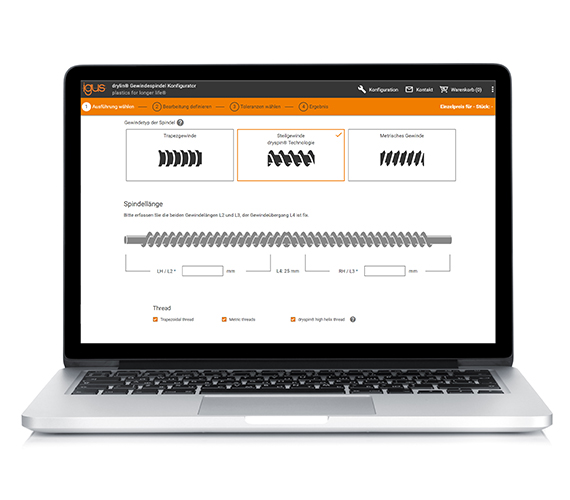

Customised lead screw machining

In addition to the standard sold by the metre goods, we also offer the possibility to machine the lead screw directly, according to the specifications of the application, simply configured online with our free lead screw configurator. Machined ends can also be individually processed using the tool. CAD software or knowledge in handling CAD programmes is not required.

Thanks to the integrated design tool, all entries are automatically checked for plausibility. A 2D dimensioned drawing and 3D step file generated directly online The live pricing also gives a good impression of the costs involved in the individual processing steps.

In addition, this online tool can also be used for special processing. Send us your drawing, we will check the manufacturability and issue you with a quotation.

Lead screw nut product range

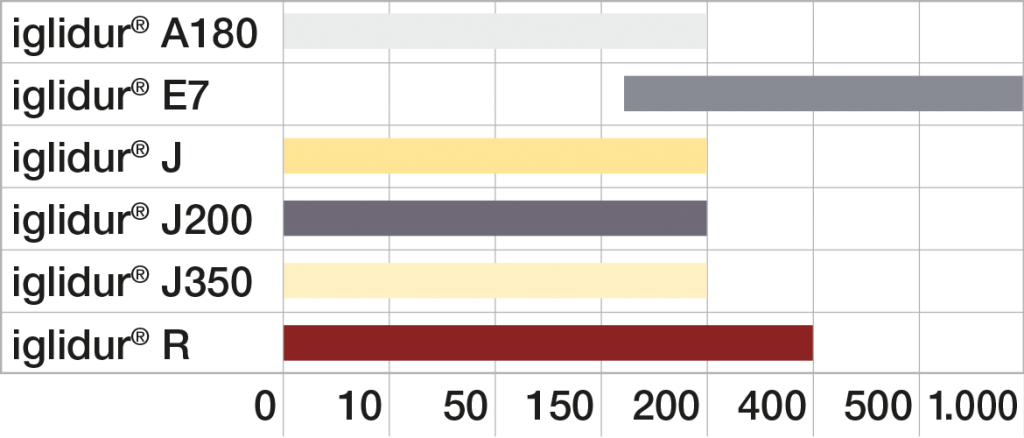

dryspin lead screw nuts are made of iglidur high-performance polymers. There are 6 different standard materials available for different applications: iglidur J, iglidur J350, iglidur A180, iglidur E7, iglidur R and iglidur W300. The use of different tribologically optimised materials enables lead screw technology to meet many of the required specifications, such as resistance to high loads, temperature resistance or FDA conformity.

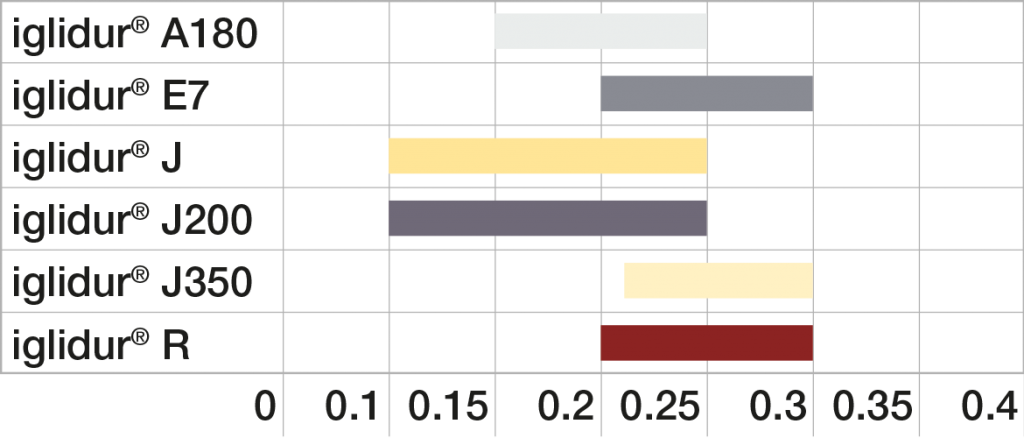

Already during the development phase, the focus is on optimising the friction properties, with the objective of attaining the lowest possible coefficient of wear and friction.

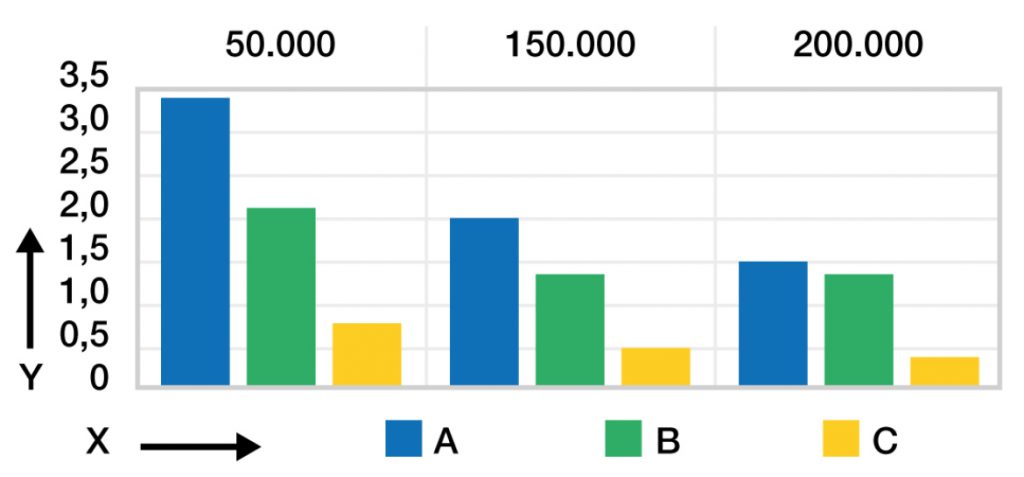

Let us take a look at the wear test of the 10×50 high helix thread:

A Blue: Standard high helix thread/POM plastic nuts

B Green: Standard high helix thread/lead screw nut igus®

C Yellow: dryspin® high helix thread/lead screw nut igus®

y = wear rate [μ/km stroke]

x = number of cycles

A standard high helix thread compared with POM plastic nut, a standard high helix thread with drylin lead screw nut and the dryspin high helix thread DS10x50 with the matching dryspin lead screw nut. The load was 36 [N] at 100 rpm, tested at 50,000, 150,000 and 200,000 cycles.

The diagram clearly shows that the dryspin technology has by far the lowest comparison rate in each cycle.

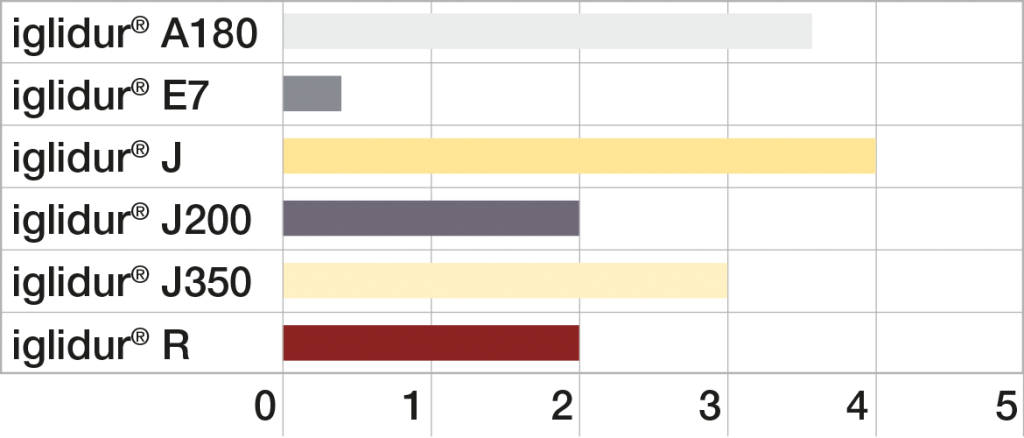

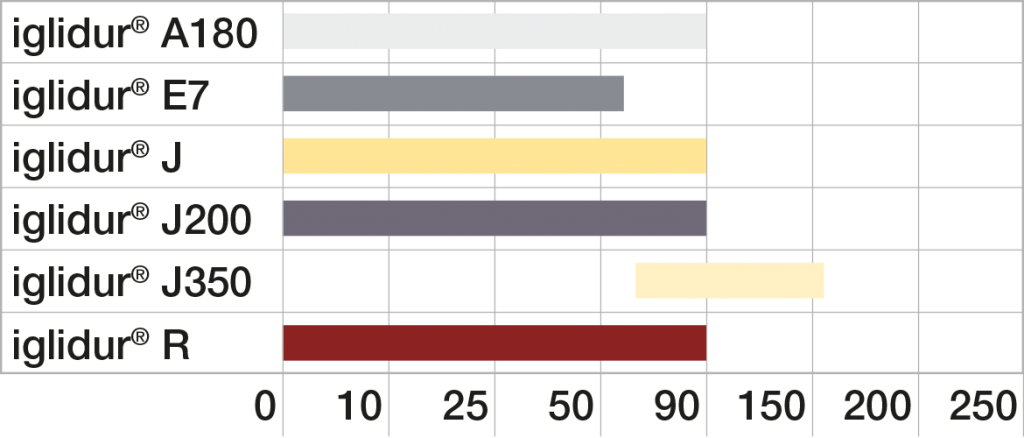

Material selection of dryspin nuts

The dryspin lead screw nuts are made of highly wear-resistant iglidur high-performance polymers and are therefore 100% lubrication-free and maintenance-free. They are durable and tough in adverse environments. They also score points with their resistance to chemicals, freedom from mould and quiet travel. All standard materials are PTFE-free. The base polymers are decisive for wear resistance, whereas the fibres and fillers reinforce the lead screw nut. In this way even high forces can be absorbed. Solid lubricants lubricate the lead screw nut independently and prevent friction of the system. This means that they can also be used in special environments, such as for example, hygiene-sensitive areas, without any problem.

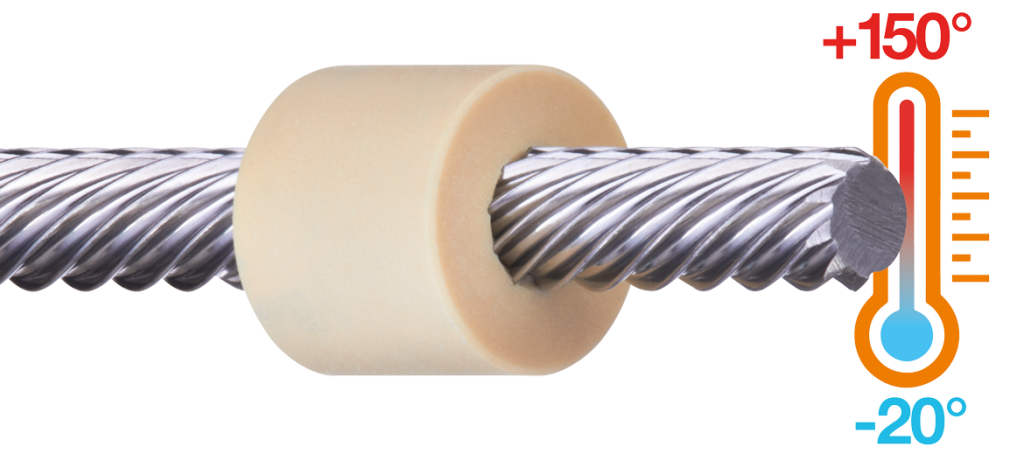

Temperature resistance also plays a major role in many applications. It is often suggested that polymer lead screw nuts can only be used at low temperatures. But that is not true!

Our standard lead screw nut JFRM-…DS10x50 made of iglidur J has an upper long-term application temperature of +90°C. The specialist for high-temperature applications, iglidur J350, can enable long-term application at +150°C. But the plain lead screw nuts not only run perfectly in the heat, but also at minus temperatures. The following applies to all standard lead screw nut materials: the lower application temperature is -20°C.

It should always be noted that the axial play in the lead screw system is directly influenced over a wide temperature range. The specifications of the axial clearance are based on laboratory tests and an ambient temperatures of 23°C.

Also observe the following: if I use a special material such as iglidur W300 or iglidur J350, it will only work in the optimum performance range with the appropriate application parameters. When using iglidur J350, for example, this means an application temperature of > 90°C. Otherwise the material cannot show the desired specifications and the standard material iglidur J is recommended.

Here all materials are summarised again:

High efficiency at all speeds: iglidur J

► High speed

► Low wear

► Best coefficient of friction

For temperatures up to +150°C: iglidur J350

► For high temperatures

► Good coefficient of friction at medium load

For medium to high speeds: iglidur R

► High wear resistance for low loads

► Low moisture absorption

► Vibration-dampening

FDA-compliant for the food and pharmaceutical industries: iglidur A180

► FDA-compliant

► For contact with food

Best counter partner for aluminium: iglidur J200

► Low coefficient of friction and wear

► Long service life

For high speeds: iglidur E7

► Low loads up to 200N

► Speeds of up to 1200rpm.

Besides a large selection of standard materials for lead screw technology, igus also offers a wide range of models in the lead screw nut geometry itself. Even lead screw nuts in injection moulding or mechanically manufactured from iglidur bar stock have already improved many applications.

Here we have put together a guide to the right choice of material:

In addition to the different versions of the lead screw nut, dryspin technology scores with something else: its numerous thread dimensions. The dryspin development team works tirelessly to develop new dimensions. We also offer almost all lead screw nuts as right-hand and left-hand threads. So we can proudly say that the dryspin product range has grown considerably in recent years and is being expanded year after year.

You can discover the variety of our dimensions in our online shop: