Plastics in passenger and engine driver seats

Thorsten Mersch | 3. April 2020

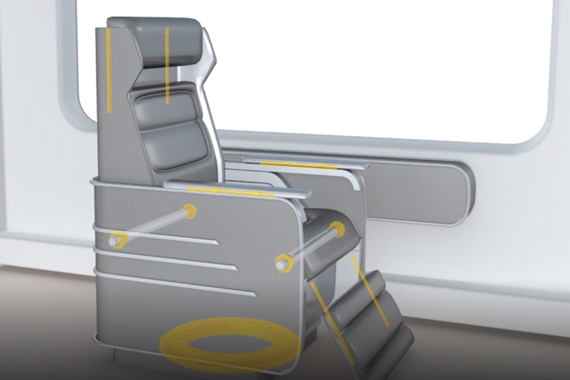

What do folding seats for metros, first-class seats on regional trains, and comfortable engine driver seats have in common? Upon first inspection, one might think it is only the obvious seat and back. But a more careful consideration reveals that each seat has polymer elements. Why polymer? Soft polymer dampens vibrations better and absorbs noise better than metallic bearings do. Imagine all 700 seats in a train vibrating. That would eliminate the rest compartments.

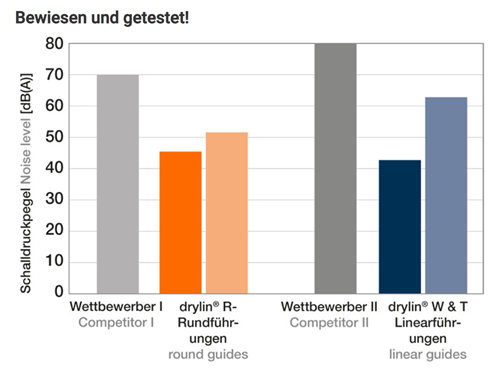

There are also linear guides with polymer sliders that are used for seat adjustment. Tests have shown that solutions incorporating polymer have one quarter of the noise of ball-guided systems.

In addition to providing a quiet run, polymers also reduce weight. Does that make a difference with just two small plain bearings in each folding chair? Probably not. But there is quite a bit more in modern seats. Footrest adjustments, glide strips in headrests and folding tables, slip rings for rotating the entire seat and height adjustment, for instance. In trains, as in aircraft, every kilogramme is precious.