Programming robots myself – how do I get started?

Adriana Glazer | 29. April 2020

After our article on “What types of robots are there, and which robot is the right one for my application?“, we now come to the truly fascinating part of cost-effective automation: how can you program robots yourself? Can you do it at all without expert knowledge? What happens during automation and offline programming?

Advantages of offline programming

Before getting to actually controlling the robot, you can start by determining robot movement sequences with offline programming. Offline programming is a procedure for simulating movement sequences without a direct connection to the actual robot. Programming is displayed via a 3D user interface. You can then use a control system to transfer the program you have written to the actual robot. This enables you to set up automation without stopping your production or process. All controlled robot movements that are programmed offline can be implemented immediately later on with the physical robot.

Programming, robot commands, robot kinematics – what you need to know

The first thing you need for programming is a computer with Windows 10. You should have a certain amount of expertise in programming so that you are familiar with the various robot commands. If you do not, it is a good idea to familiarise yourself with simple programming with our support or the YouTube channel. The programmer should also be familiar with the X, Y, & Z Cartesian co-ordinate system so as to understand the direction in which the robot kinematics move. This will avoid program error messages and collisions.

Robot programming: your first steps

Once you have the expertise, you can start programming. A teach-in function makes programming the robot very easy, even without a robot connection. The user must manually move the robot to the desired position and define how it is to travel to that position. The process is repeated until the desired motion profile is created. This profile can then be stored and loaded. Now we come to the Ethernet interface, which is how the program written offline can be transferred to the physical robot. After the robot is commissioned and referenced, the connected robot can immediately transfer the program created offline to the physical robot and run it.

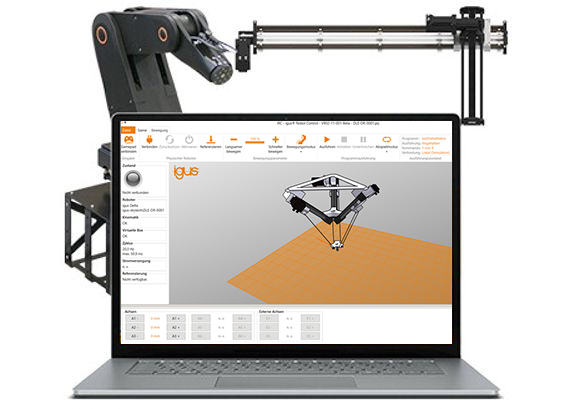

Ideal introduction to automation with igus Robot Control

The user-friendly igus Robot Control software with its control system is the ideal overall package for you if you want to program your robots yourself. The control system can be used by both beginners and veterans and is suitable for articulated arm robots, delta robots and Cartesian robots.

The software offers user-friendly operation and programming commands such as individual axis movement or linear movements in which all axes can move simultaneously. The Ethernet interface ensures a quick connection between robot and software. The software allows for easy robot referencing, movement and programming. Commands such as if-then-else, loop, and digital I/O can be programmed directly in the software. Pre-configured grippers and cameras in the software greatly facilitate application implementation.

Download igus Robot Control software free of charge

To enable users to determine in advance which robot is best suited to their application, igus now offers igus Robot Control, software for simulating and programming all igus robots. “As a mechanical engineering company, we are very familiar with the different kinematics, so the next logical step for us was to develop a correspondingly simple and intuitive robot control system”, says Alexander Mühlens, Head of Automation Technology at igus GmbH. What is special about this offer is that the software is available free of charge online and is licence-free.

Please contact us!

About the author:

Julian Ruwe

Technical Sales low cost automation robolink and drylin

Phone: +49 2203 9649-8255