A (long) lifetime of the car without lubrication

Dirk Tietz | 13. May 2020

Many bearing positions in vehicles have to work without external lubricants such as grease or oil for their entire life, but must not fail or cause noise. How is this possible over many years?

There are basically several types of lubrication:

- Consumption or loss of lubrication: old lubricant is continuously or cyclically replaced by new one. Frequently used, e.g. on agricultural machinery, which must be regularly lubricated via grease nipples. But you can hardly find them on modern cars anymore.

- Circulating lubrication: the classic lubricant flow in the combustion engine with oil sump, pump and filter. Oil is forced by a pump through channels at high pressure to wherever it has to go for lubrication. The oil must be replaced regularly due to deterioration, dilution and contamination.

- Splash lubrication: lower gears of a gearbox are constantly in oil and when moving they carry the lubricant to bearing points or gears that are positioned too high.

- Service life or initial lubrication: e.g. actuators in vehicles require a common lubrication during production. Grease is applied once and the bearing position is then often sealed or encapsulated.

- Self-lubrication: first, low-wear friction partners can be combined with a low coefficient of friction. On the other hand, and much more frequently, solid lubricants (e.g. graphite, PTFE etc.) are directly integrated into the bearing material

Tribology specialists like igus GmbH concentrate on self-lubricating polymer bearings as they offer additional advantages over metal, ceramic or other bearing materials.

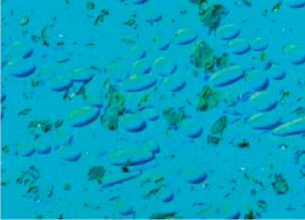

Materials are developed under the brand name iglidur, which ensure extremely low coefficient of friction by the addition of solid lubricants. Depending on the application and desired performance, different fibre materials are also integrated to enable enormously high loads on the bearing. During movement, the homogeneously distributed solid lubricants are released and ensure self-lubrication.

Homogeneous iglidur tribopolymer under the microscope:

Even with higher wear, optimum lubrication is ensured over the entire bearing thickness. This is a clear advantage over very thin PTFE-coated metal bearings, which, after damage or abrasion of the coating, only offer emergency running properties. Bearings soaked in oil require relatively high surface speeds to distribute their oil. If this has evaporated or is resinified after some time, only emergency running properties are available.

For roller or ball bearings made of metal, the loss or lack of lubricant also means a quick end. If the technical parameters permit the use of plain bearings (e.g. p*v value, temperature), they offer a technical advantage in addition to the costs.

We would be pleased to present further advantages and possible applications of our tribologically optimised polymer plain bearings.

Feel free to talk to me:

Dirk Tietz

Phone: +49(0)2203-9649-562

Mobile: +49(0)173-7626993

E-mail: dtietz@igus.net

Free online consultation: igus Chat, Teams, Skype, Whatsapp, WeChat

Follow us on: LinkedIn, Instagram, Facebook

Have fun browsing and thanks for your time.

PS: whether plain bearings, spherical bearings, linear bearings, ball bearings, special sliders, gears or individually customised design, the iglidur Designer leaves nothing to be desired. Request part now and receive a quote by tonight.

More information: Automotive industry, polymer plain bearings for automotive interior, exterior and engine compartment applications