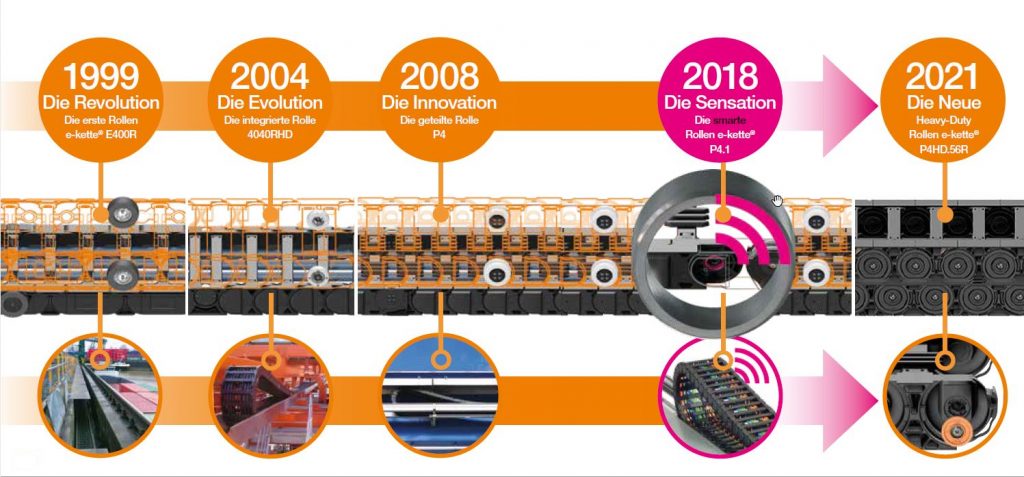

20 years igus rol e-chains

Jens Göbel | 17. March 2020

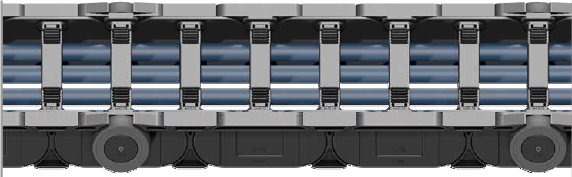

In 1999 a mile stone was set for igus with the installation of the first igus rol e-chain for a 130m crane travel at a river port in Germany. The integration of roller into the side part of the chain link helped to significantly reduce the coefficient of friction and therefore the energy needed to move the chain system. The rol e-chain opened the doors to travels beyond 100m and became the standard for crane applications.

Heavy Duty rol e-chain

The introduction of the heavy duty rol e-chain version in 2004 provided users with a higher durability and life time of the chain system on the crane. It became the new standard for the cable management for the trolley travel on Ship-to-Shore (STS) cranes.

P4 rol e-chain

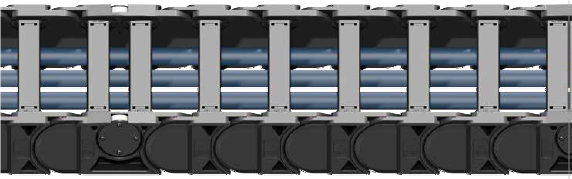

Even though the heavy duty rol e-chain is still used today on many new STS cranes, the premier of the split roller design P4 chain in 2008 has since then taken the lead for any kind of high speed (<240m/min.) and low noise crane trolley installations, as you can find them on the latest STS and automated stacking cranes (ASC) for instance.

P4.1 rol e-chain

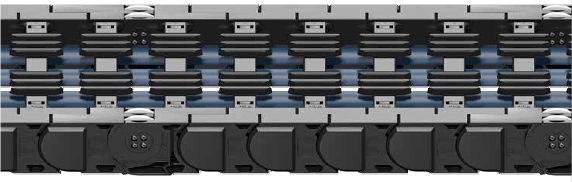

In 2018 the P4.1 was launched. It set new records in terms of speed (<300m/min.) and most importantly life time. The later is achieved by the implementation of an igus tribo-polymer plain bearing in the connection of the e-chain links. iglidur® polymer plain bearings are another interesting product range from igus® that is used here for the first time in series in an e-chain®.

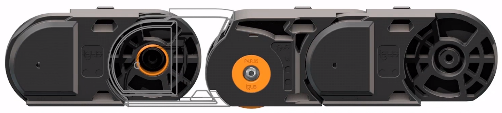

P4.HD rol e-chain

The latest generation of the P4 chain series is the heavy duty version, P4.HD. It is not just a P4.1 with wider side links. With the P4.HD a new chain link design has been introduced to the market. To increase the stability of the chain, the links are now connected via a fork / tab connection and a larger stop dog surface has been implemented. Just like the P4.1, bearing bolts made from special tribo-polymer material ensure the lowest possible wear between the links.

Predictive maintenance with intelligent components from igus®

As an option, the chain now also be fitted with a wear sensor, to reliably predict the expected service life of the chain system. The wear sensor is part of the igus isense condition monitoring and life time prediction product family.

With over 1,720 STS e-chain installations (including over 570 with the P4 chain series) and more than 8440 RTG, (A)RMG and ASC installations worldwide (since 1999), the igus® rol e-chain has conquered the port crane market. https://www.igus.eu/info/industries-crane-industry