The solution to a shrinking circular economy: a simple, reliable recycling platform

igu-blog-adm | 2. November 2023

The global circular economy is shrinking. It is high time to act.

One solution would be to recycle technical plastics, but that has so far been quite cumbersome.

We will show you how plastic recycling is finally becoming easy.

Climate change is progressing, and more and more branches of industry are struggling with material shortages. These are two good reasons why valuable materials should, in the future, no longer be disposed of with industrial waste and incinerated, but instead be reused. The term “circular economy” is on everyone’s lips, suggesting that recycling rates are increasing. Unfortunately, the opposite is the case.

The circular economy is shrinking

The Circularity Gap Report 2023 by the Circle Economy Foundation and the Deloitte Group shows this clearly: The global circular economy has shrunk from 9.1 per cent in 2018 to 7.2 per cent now.

“The circular economy is the key to curbing both the climate crisis and the loss of biodiversity. So the size of the gap between the current global economy and a comprehensive circular economy is alarming, even though the importance of the latter is repeatedly underscored by politicians and companies,” says Rebecca Tauer, Circular Economy Programme Manager at WWF Germany. “And the widening of this gap is dramatic because we are taking more and more resources from the planet, using them for far too short a time, and throwing them away. We’re on the wrong track. The report’s message is clear: We need to move from talking to doing.”

From talking to doing – igus has heard the call

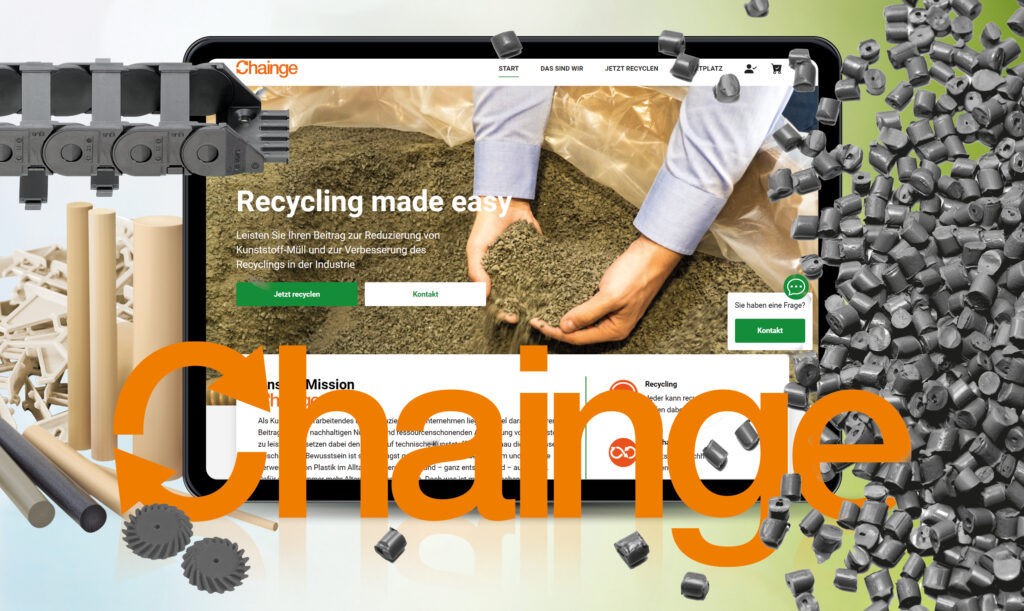

To accelerate the transition from a linear economy to a circular economy, igus launched a technical plastics recycling programme: chainge.

The idea is to make recycling simple at long last. But it has so far not been obvious that this can be done. For example, users of energy chains for guiding power cables and hoses in machines and systems are repeatedly faced with several questions: Who is responsible for recycling the chains? Will they be recycled properly? And what happens to the recycled material?

The answers are often so complicated that the chains simply end up in industrial waste and are incinerated. The emissions pollute the environment, valuable plastics are lost to the circular economy forever, and there is an uneasy feeling that things aren’t going as they should. And then there are the disposal fees.

Recycling is easy with chainge

But it doesn’t have to be like that. The chainge.igus.de online platform offers a simple, reliable alternative. Owners of worn-out energy chains can have them recycled on the platform, keeping them in the circular economy. They can do this in just a few steps:

- Collect, clean, and weigh old energy chains

- Make a recycling request

- Send old chains to igus

- Receive a voucher from igus

At igus, old chains are processed into recycled material used to manufacture new products, such as the cradle-chain E2.1.CG, the first energy chain made entirely from recycled plastic. The voucher can then be used to purchase these or other igus products.

“The special thing about igus is that you get everything from a single source. We are a plastics producer and supplier, an assembly service provider, a disposal company, and a producer and supplier of recycled material used to create new products,” says Michael Blaß, igus e-chain systems CEO. “What we offer is unique in this form and enables us to work with our customers to turn plastic into a sustainable resource.” So the company also strives to integrate further locations into chainge and increase capacities in order to make an even greater contribution to the circular economy.

The first steps towards sustainable plastic utilisation have been taken

Since the chainge launch in 2019, the programme has rapidly gained momentum. igus has saved almost 100,000 kg of high-performance plastic from incineration and returned it to the circular economy. Recycling has now been extended beyond energy chains to smaller components made of technical plastics, such as gears and bar stock.

“It is the innovative power of entrepreneurs that finds, applies, and passes on solutions,” said Sven Gebhard, Vice President of the Cologne Chamber of Industry and Commerce, during his laudatory speech at the Going Circular competition, in which igus took first place with chainge. The contest, he said, is aimed at raising awareness of the circular economy mega-issue and motivating other companies to look for ways to conserve resources themselves. “This is how global climate protection can succeed.”

Plastics production in Germany is to be independent of crude oil by 2045

Politicians are pursuing an ambitious goal for the circular economy, that of largely using circular raw materials in plastics production starting in 2045. To accelerate this development, chainge offers more than plastic recycling. Injection moulding companies from all over the world can also purchase recycled materials on the platform from which sustainable products can be manufactured. The platform can also be used to sell recyclates. Recyclers can become chainge partners and sell their material on the marketplace.

“The holistic closing of material cycles is a central key to sustainable economic activity and thus to achieving climate targets,” says Holger Lösch, Deputy Managing Director of the Federation of German Industries (Bundesverband der Deutschen Industrie, or BDI), on the founding of the BDI Circular Economy initiative. “Thanks to its high level of technological expertise, Germany as an industrial location has enormous potential to become a leading provider of new technologies that allow economically viable raw material recycling and reduce dependence on raw material imports.”